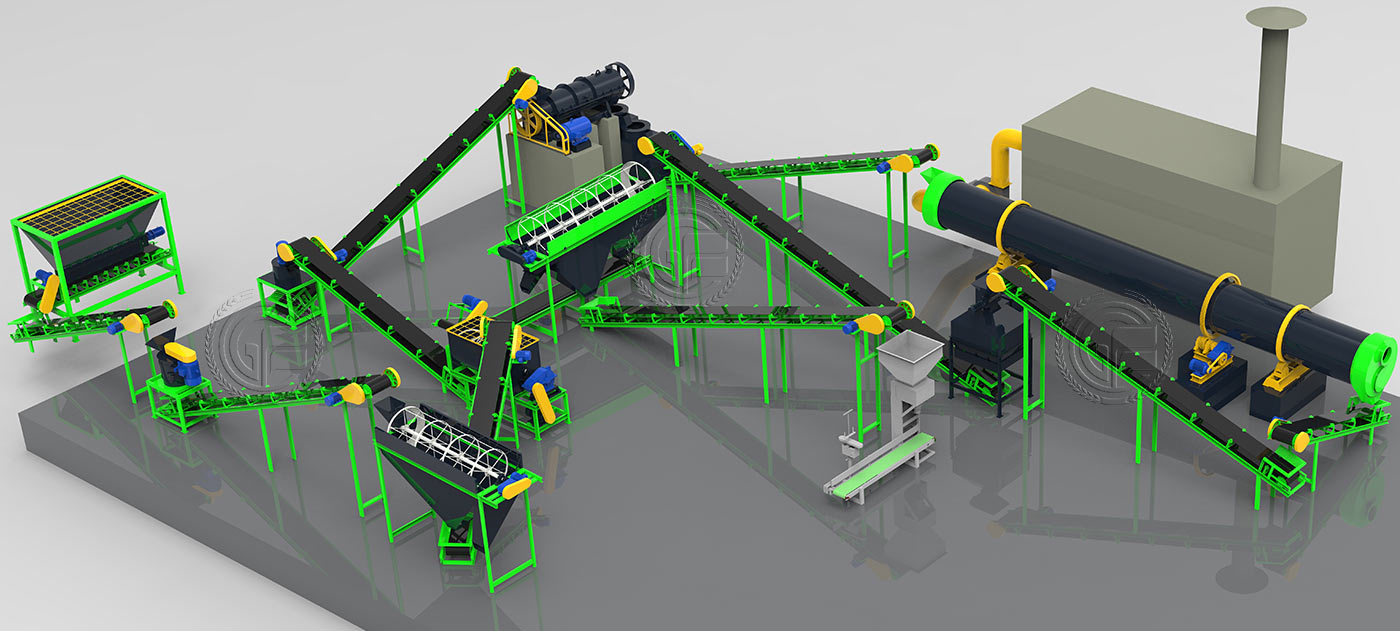

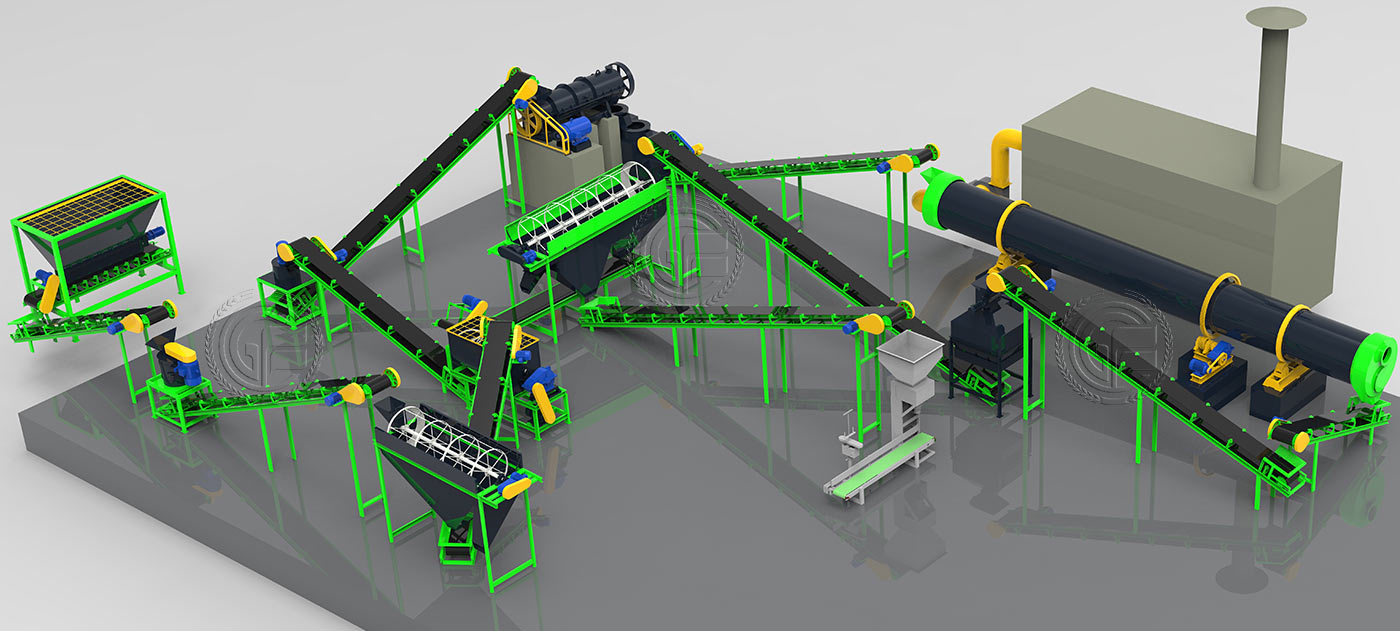

The Stirring tooth granulation production line uses high-speed rotating agitators to generate mechanical and aerodynamic forces to achieve material mixing, granulation, spheroidization, and densification, directly converting powders or high-humidity materials into uniform spherical granules. The agitator speed and drum angle can be adjusted according to the raw material characteristics to precisely control granule size and strength, meeting the molding requirements of different fertilizer products.

Core Features

Corrosion-resistant design: The drum can be lined with a special rubber sheet or acid-resistant stainless steel, automatically removing scars and tumors to resist corrosion from acidic and alkaline raw materials, extending equipment life by over 30%.

Flexible control: Particle size and strength can be precisely controlled by adjusting parameters such as agitator speed and drum angle, allowing for quick switching between production specifications.

High-humidity compatibility: Designed for high-humidity organic raw materials, it prevents agglomeration and blockage, ensuring continuous and stable operation.

Integrated Operations: The production line integrates raw material transportation, granulation, screening, and other processes, achieving integrated production and reducing manual intervention.