Organic fertilizers come from a wide range of sources, encompassing animals, plants, industry, and daily life, embodying the ecological concept of resource recycling.

Organic fertilizers play a comprehensive role in agricultural production. They not only provide nutrients for plants but also improve soil structure, enhance microbial activity, and increase soil fertility and water retention, making them an all-around guardian of soil health.

Depending on their production method and raw material source, organic fertilizers are primarily categorized as farmyard manure, green manure, and commercial organic fertilizers.

Common Granulation Methods

Organic fertilizers are mostly made from livestock and poultry manure, straw, and other raw materials, which contain crude fiber and high moisture content. Therefore, granulation equipment must be adapted to their high viscosity and tendency to agglomerate.

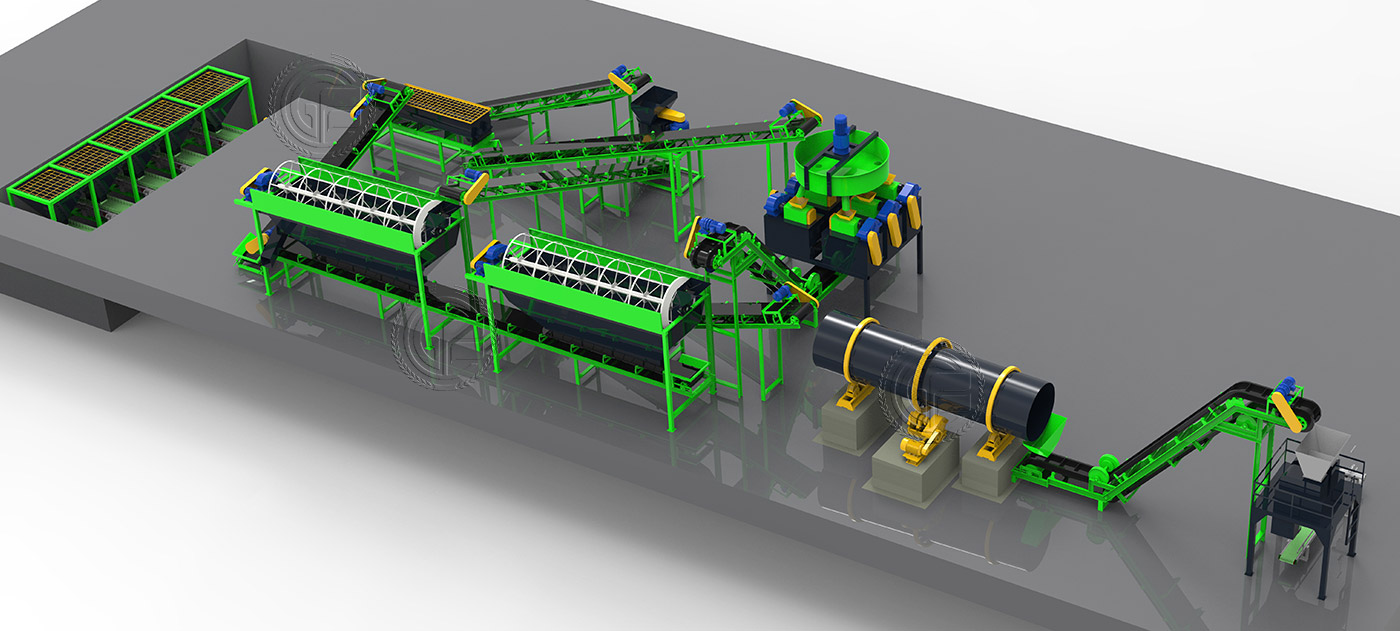

Extrusion Line

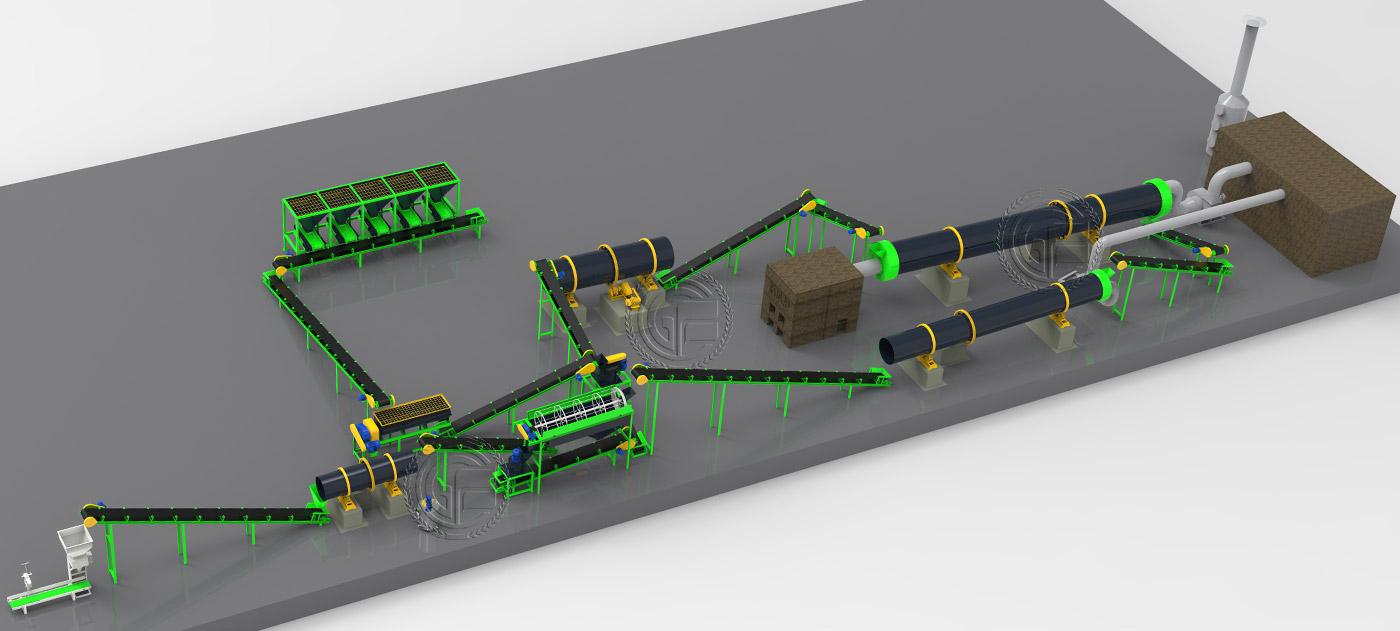

Disc Line

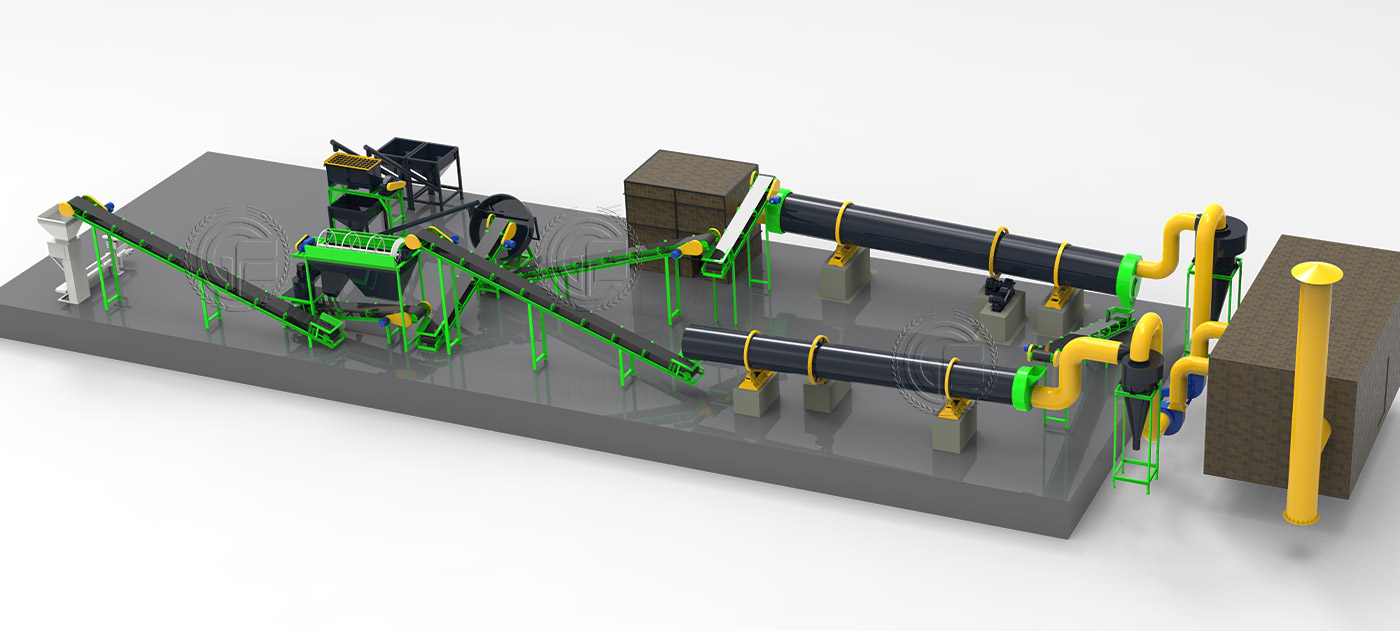

Drum Line

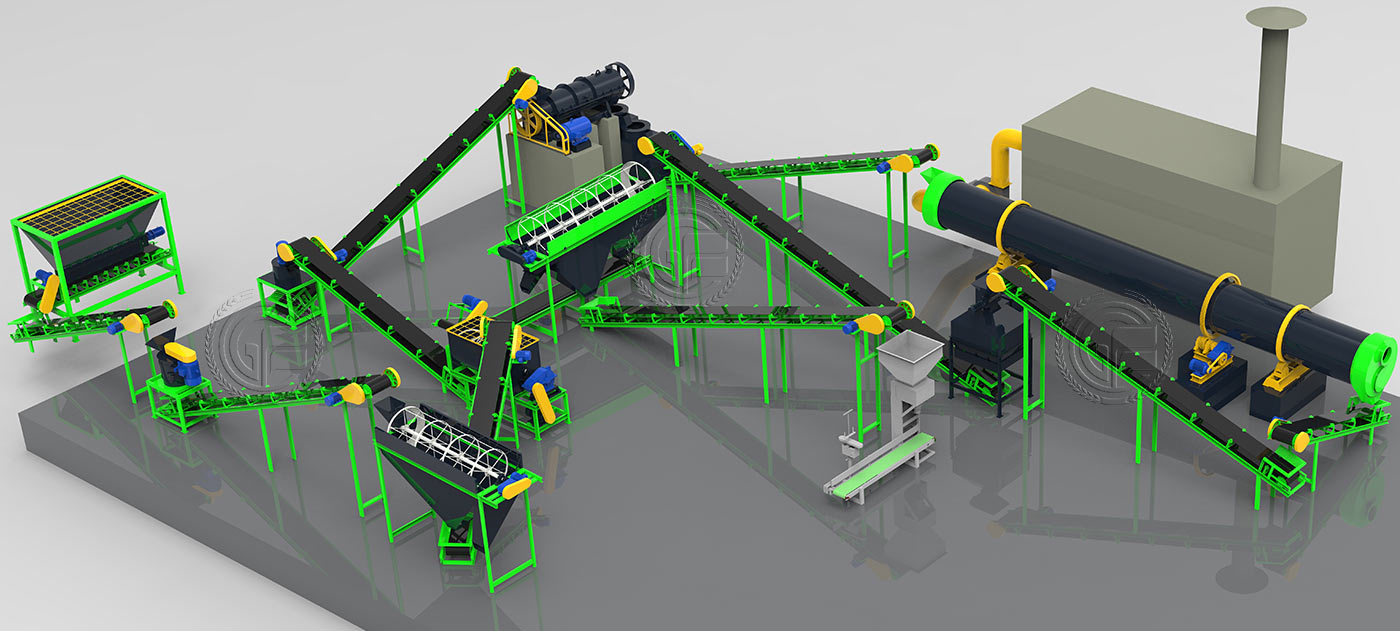

Agitator Line

Production Process

Raw Material Collection and Pretreatment → Fermentation and Decomposition → Crushing and Screening → Ingredient Mixing → Granulation → Drying and Cooling → Screening and Packaging

Characteristics of Organic Fertilizer

Natural Source: Primarily derived from animal and plant residues or excrement (such as manure, straw, cake meal, green manure, kitchen waste, etc.), fermented and decomposed.

Soil Improvement: Rich in organic matter, it significantly improves soil structure (increasing aggregate structure, increasing air permeability, and retaining water and nutrients), thereby enhancing soil fertility.

Comprehensive but Slow-Delayed Nutrient Release: Contains nitrogen, phosphorus, potassium, and various trace elements, providing comprehensive nutrition. However, the nutrient release is slow and prolonged, requiring microbial decomposition before plant absorption.

Eco-friendly: Promotes soil microbial activity, reduces environmental pollution (resource recycling), and long-term use benefits ecological agriculture and soil health.

Professional Technical Support

We provide full-process technical support, from material testing to equipment selection, to customize the most suitable granulation solution for you.

Based on material characteristics and production capacity requirements, we provide precise equipment selection recommendations to ensure maximum production efficiency.

Provide complete production line planning and design, from raw materials to finished products, to optimize processes, reduce energy consumption, and improve product quality.

Leave your message