Organic-inorganic compound fertilizer is a new type of fertilizer made by mixing organic materials with inorganic fertilizers in a specific ratio. It retains the ecological properties of organic fertilizers while embodying the nutrient efficiency of inorganic fertilizers, and is playing an increasingly important role in agricultural production.

The organic component of organic-inorganic compound fertilizers primarily comes from decomposed livestock and poultry manure, straw, municipal sewage sludge, and edible fungus residue. The inorganic component is primarily composed of nitrogen, phosphorus, and potassium fertilizers, or compound fertilizers such as urea, monoammonium phosphate, and potassium sulfate. This strategically balanced combination of organic and inorganic fertilizers achieves a “fast and slow” nutrient delivery.

Common Granulation Methods

Due to the different properties of inorganic fertilizer raw materials, different granulation methods are required. For example, ammonium dihydrogen phosphate is generally granulated using a wet method, suitable for a drum granulation line; potassium chloride is generally granulated using a dry method, suitable for an extrusion granulation line.

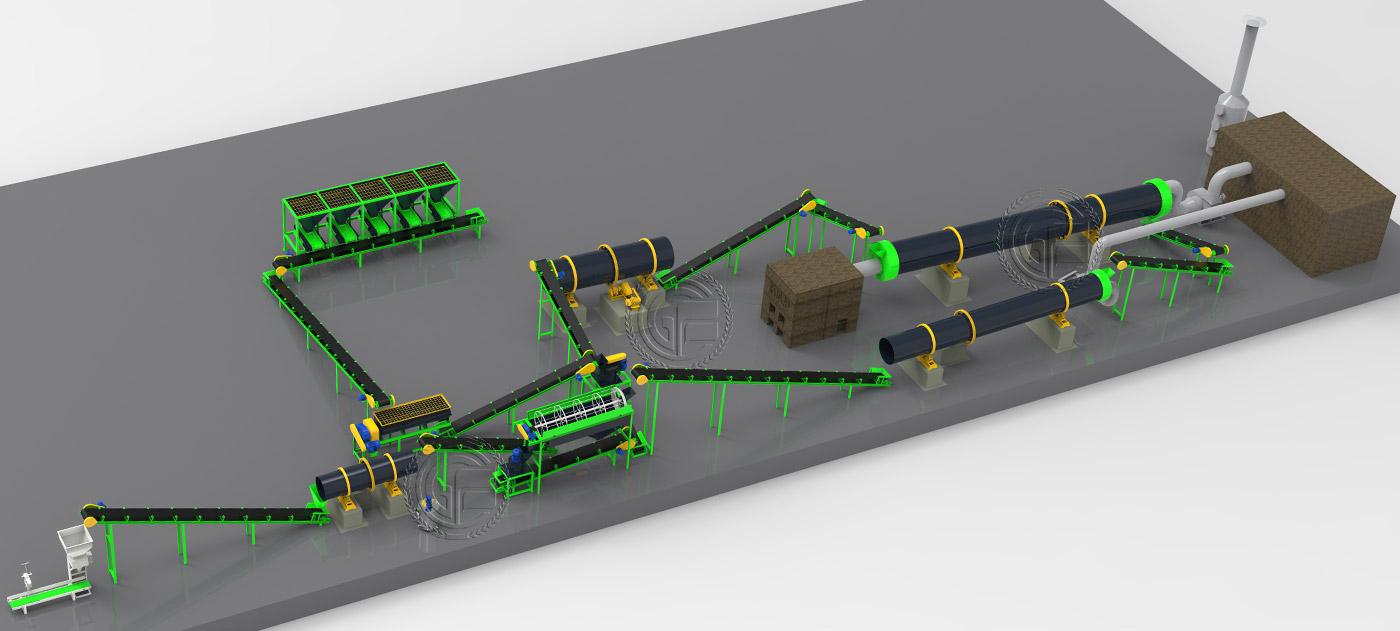

Drum granulation line

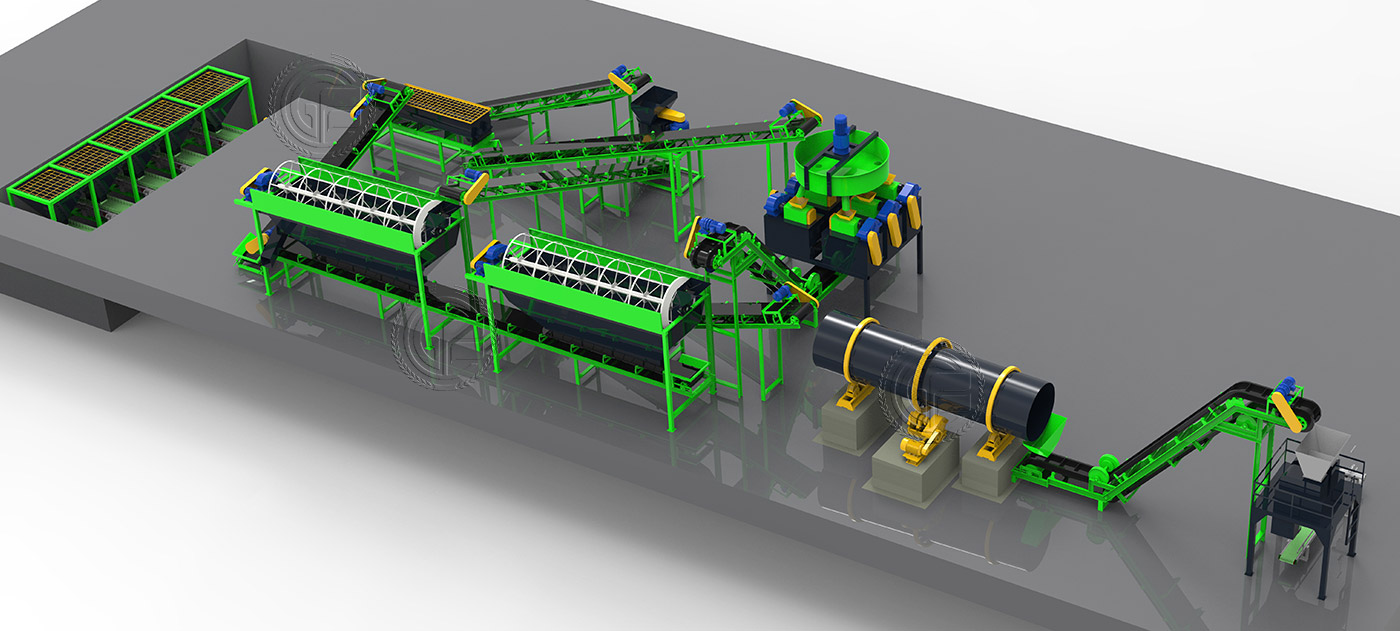

Extrusion granulation line

Production Process

Raw material collection and pretreatment → Fermentation and decomposition → Crushing and screening → Ingredient mixing → Granulation → Drying and cooling → Screening and packaging

Features of organic-inorganic compound fertilizers

Nutrient complementation: Organic ingredients (humic acid and amino acids) are combined with inorganic nitrogen, phosphorus, and potassium to achieve both long-lasting and rapid effects.

Improvement and efficiency: It enriches the soil while increasing crop absorption and utilization of chemical fertilizers, reducing waste.

Wide applicability: Suitable for all types of soil and crops, especially for ecological farming and soil remediation.

Safety and environmental protection: It reduces the risk of soil acidification and compaction caused by pure fertilizers, while also enabling waste-to-resource conversion of organic fertilizer raw materials.

Professional Technical Support

We provide full-process technical support, from material testing to equipment selection, to customize the most suitable granulation solution for you.

We provide precise equipment selection recommendations based on material characteristics and production capacity requirements to ensure maximum production efficiency.

We provide complete production line planning and design, from raw materials to finished products, to optimize processes, reduce energy consumption, and improve product quality.

Leave your message