Double-roller extrusion granulators are widely used in fertilizer production, suitable for granulating various fertilizers such as organic fertilizers, compound fertilizers, mineral fertilizers, and slow-release fertilizers.

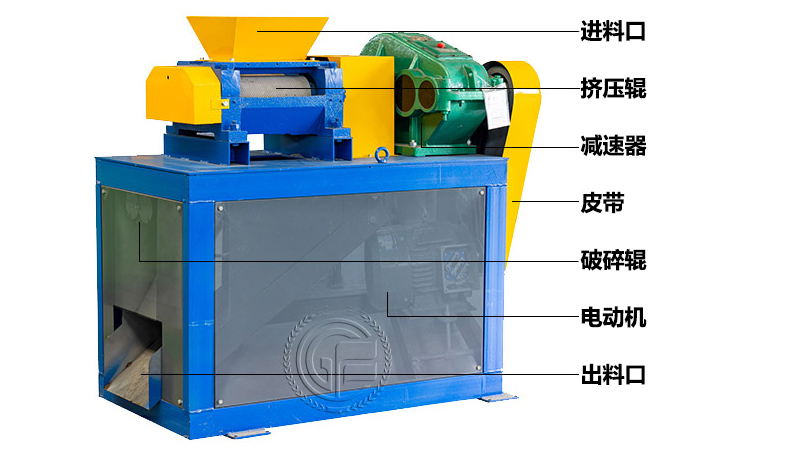

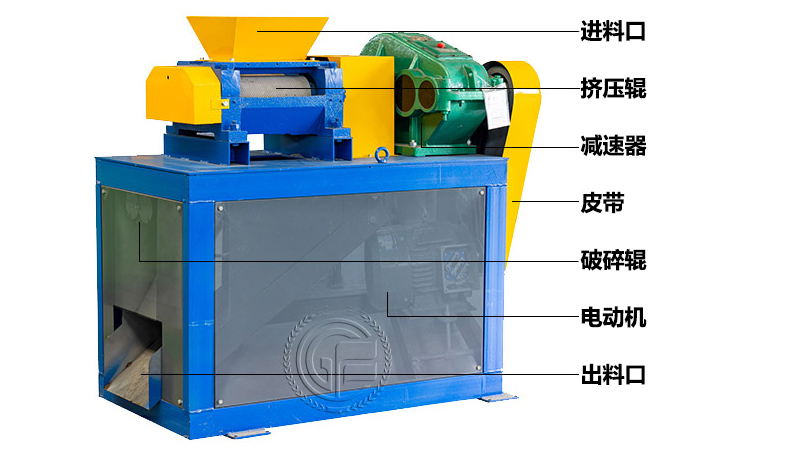

The double-roller extrusion granulator consists of five main parts: a feeding system, an extrusion system, a crushing system, a screening system, and a transmission system.

The equipment adopts a split-frame design, with the pressure rollers and transmission system independently arranged for easy daily maintenance and component replacement.

Working Principle

The double-roller extrusion granulator uses a dry granulation process, eliminating the need for added moisture or binders. Pre-treated dry powder raw materials are fed between two opposing rotating pressure rollers by the feeding system. Under the pressure of the double rollers, the raw material is extruded into dense flakes; these flakes then enter the crushing system and are broken into irregular particles by the crushing blades.

Features

High efficiency and energy saving: Dry granulation eliminates the need for drying, reducing energy consumption by more than 40% compared to traditional wet granulation. It also offers strong production continuity, with a single unit capable of producing 1-10 tons per hour. Excellent formability: The special textured design of the pressure rollers ensures uniform force on the material, resulting in a stable granulation rate of over 85%. Granule strength reaches 2-5N, exhibiting strong resistance to breakage, making it suitable for long-distance transportation and mechanized fertilization.

Flexible adaptability: By changing different pressure roller specifications, granules ranging from 2-10mm can be produced. Adjusting the pressure roller speed (50-150 r/min) and pressure allows for adaptation to various dry powder raw materials, including organic fermented materials, inorganic mineral powders, and compound fertilizer raw materials.

Roller Extrusion Granulator Components

Applications and Materials

Roller extrusion granulators are among the most widely used equipment in the granulation field, especially when high output is required.

Ammonium Phosphate (MAP, DAP)

Ammonium Sulfate

Biosolids

Compost and Other Organic Materials

Manure (Cattle, Pigs, Poultry)

Nitrogen, Phosphorus, Potassium

Phosphate

Potassium

Sulfate

Superphosphate

Urea

Images