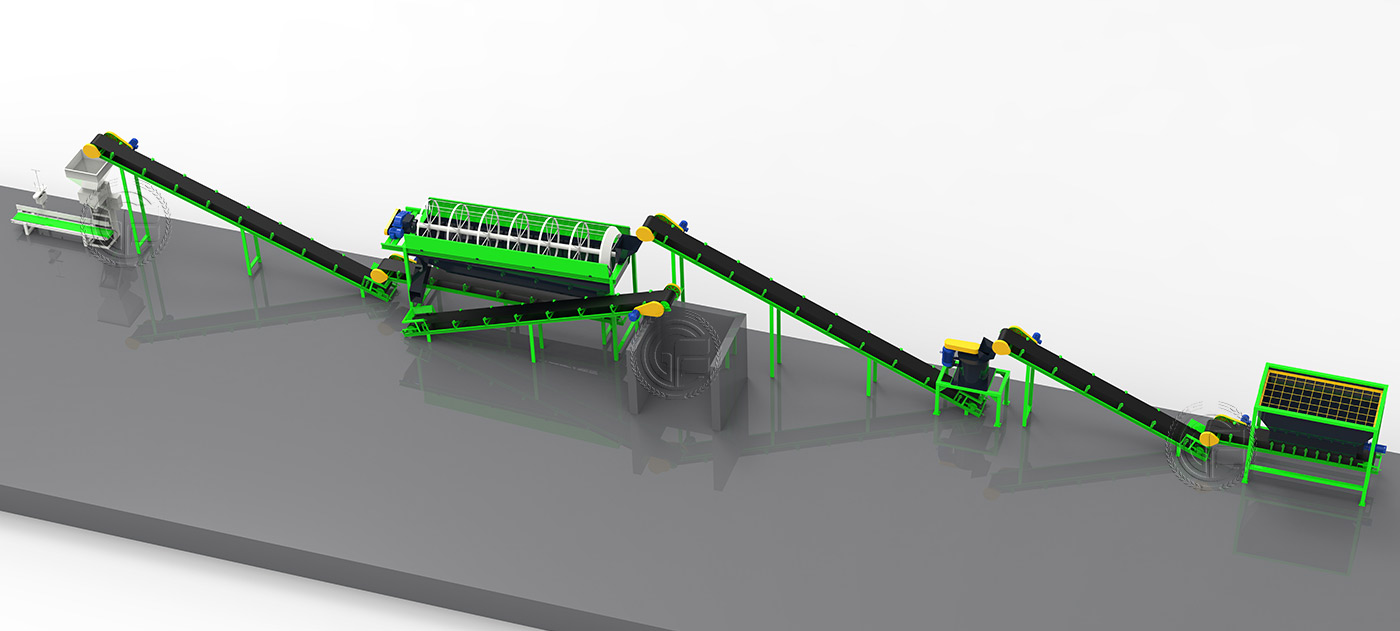

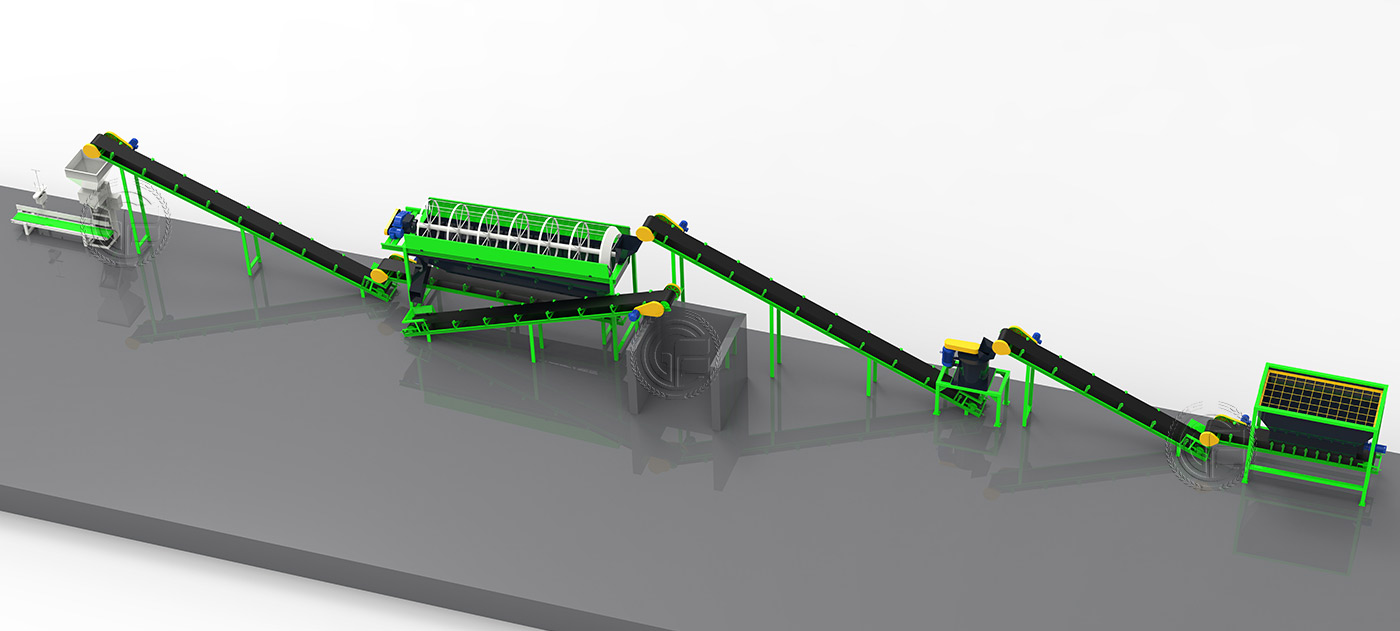

The powdered fertilizer production line is an automated system that integrates raw material processing, precise proportioning, homogenizing, and finished product packaging. Designed specifically for the efficient production of high-quality powdered fertilizers, it is widely used in the large-scale production of various powdered fertilizers.

Core Features

Modular Configuration: Flexibly combine equipment based on production capacity requirements (0.5-10 tons per hour), supporting the production of multiple fertilizer varieties on a single line. Changeovers are easy and clean, with recipe switching completed within 30 minutes.

Intelligent Control System: Equipped with a PLC human-machine interface, it can store over 500 recipes, enabling one-click production process initiation and real-time monitoring of all parameters (such as mixing time and batching accuracy), reducing manual operation.

Clean and environmentally friendly design: All contact areas are constructed of 304 stainless steel to minimize residue and corrosion. Equipped with a pulse dust removal system, the dust emission concentration is ≤10mg/m³, meeting international environmental standards.

Low-temperature process assurance: No high-temperature treatment is required throughout the entire process, preventing the inactivation of heat-sensitive components such as humic acid and biological bacteria, resulting in a nutrient retention rate exceeding 98%.