A drum granulation production line utilizes a tilted, rotating drum (drum) to agglomerate and granulate materials through rolling and tumbling. It features high production capacity, strong adaptability, and uniform granulation.

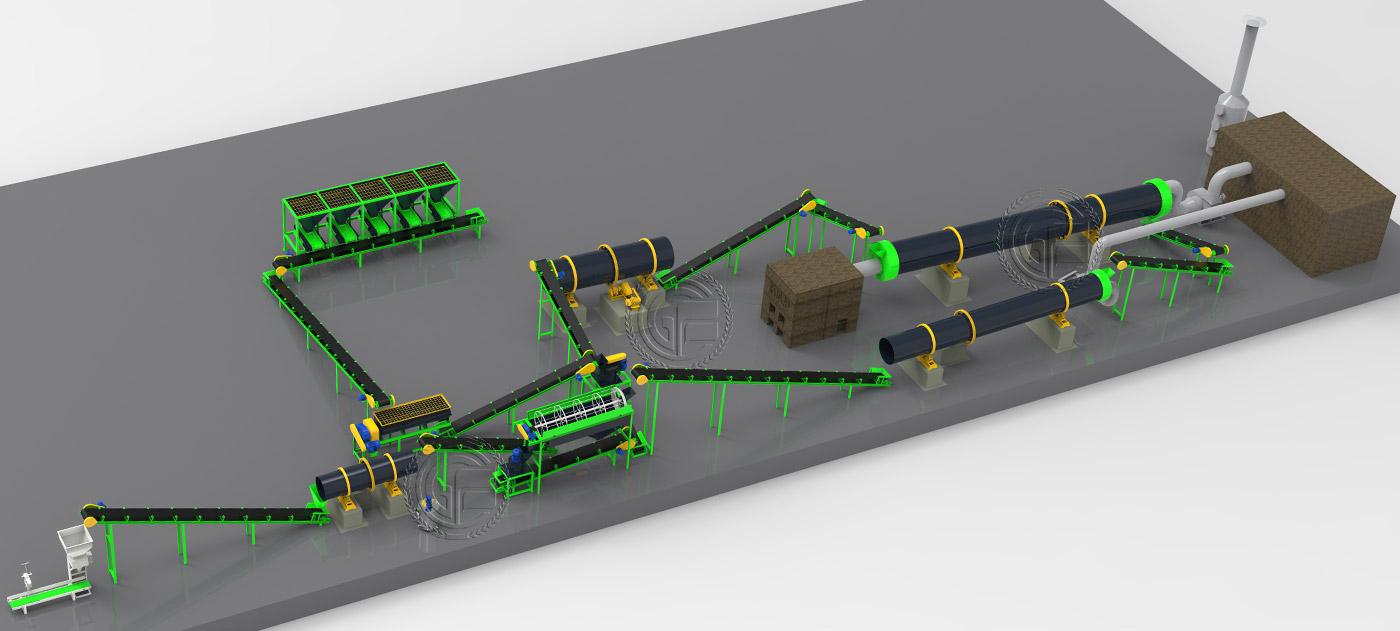

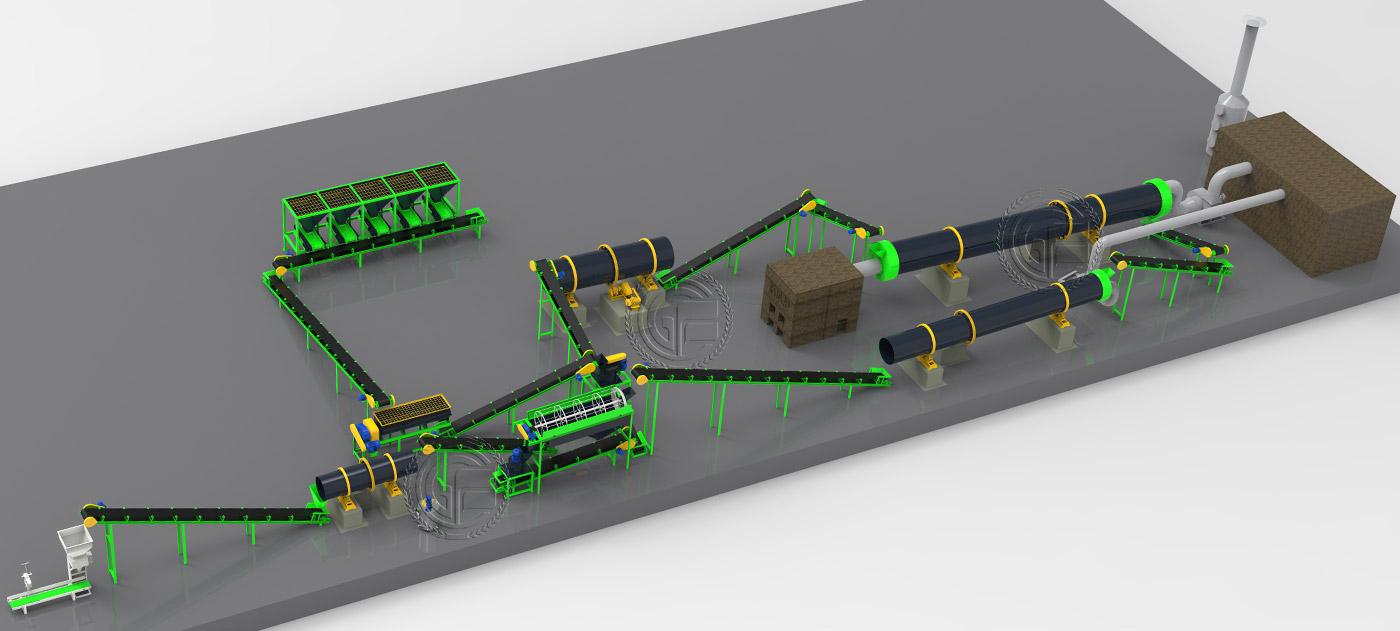

General process flow: Raw material crushing → mixing → humidity adjustment → rotary drum granulation → screening → drying → cooling → packaging.

Core Features

High Production Capacity: The drum has a large capacity, allowing a single line to achieve an hourly production capacity of 5-30 tons, making it suitable for large-scale industrial production.

Stable Granule Quality: The material is thoroughly tumbled within the drum, resulting in granules with good sphericity, uniform particle size distribution, and moderate strength, making them easy to store and transport.

High Adaptability: The line can process a variety of materials, including fertilizers, organic fertilizers, and chemical raw materials. Adjusting the water addition, rotation speed, or adding a binder allows for adaptability to materials of varying viscosities.

Easy to operate: The equipment features a relatively simple structure, few wearing parts, and low maintenance costs. The automated control system allows for precise parameter adjustment, minimizing manual intervention.

It can be combined with other processes, such as spray granulation, to produce coated slow-release fertilizers, expanding product offerings.