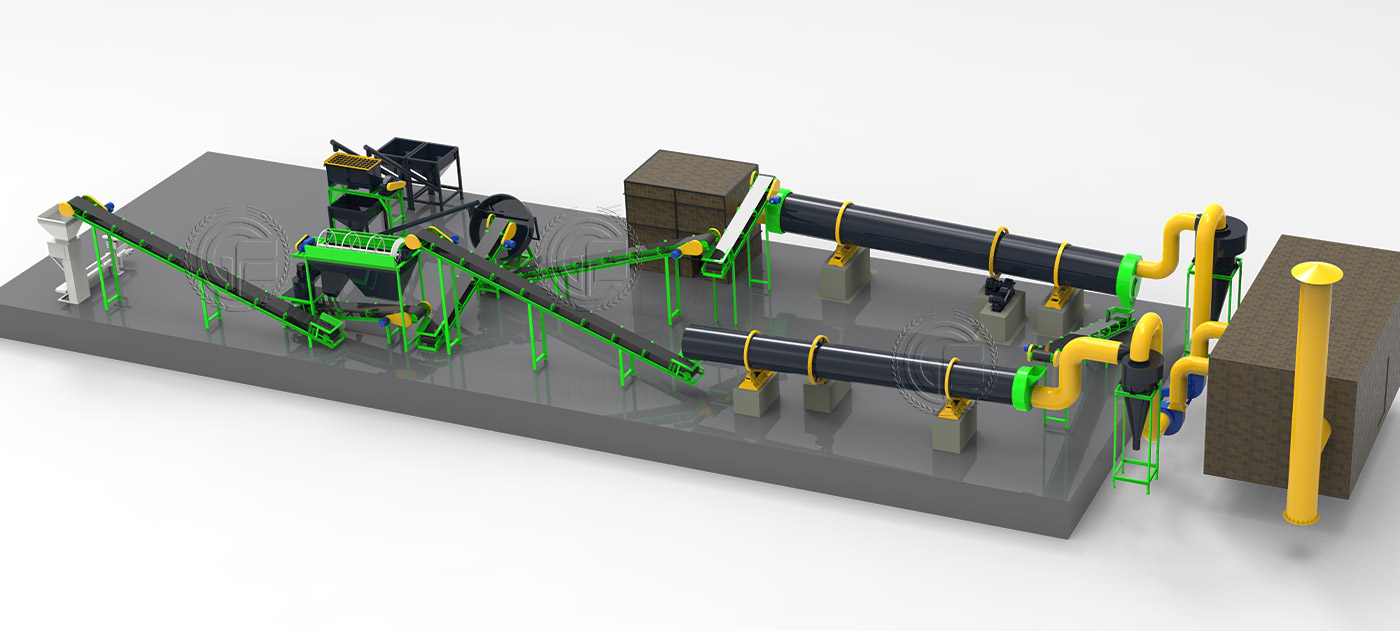

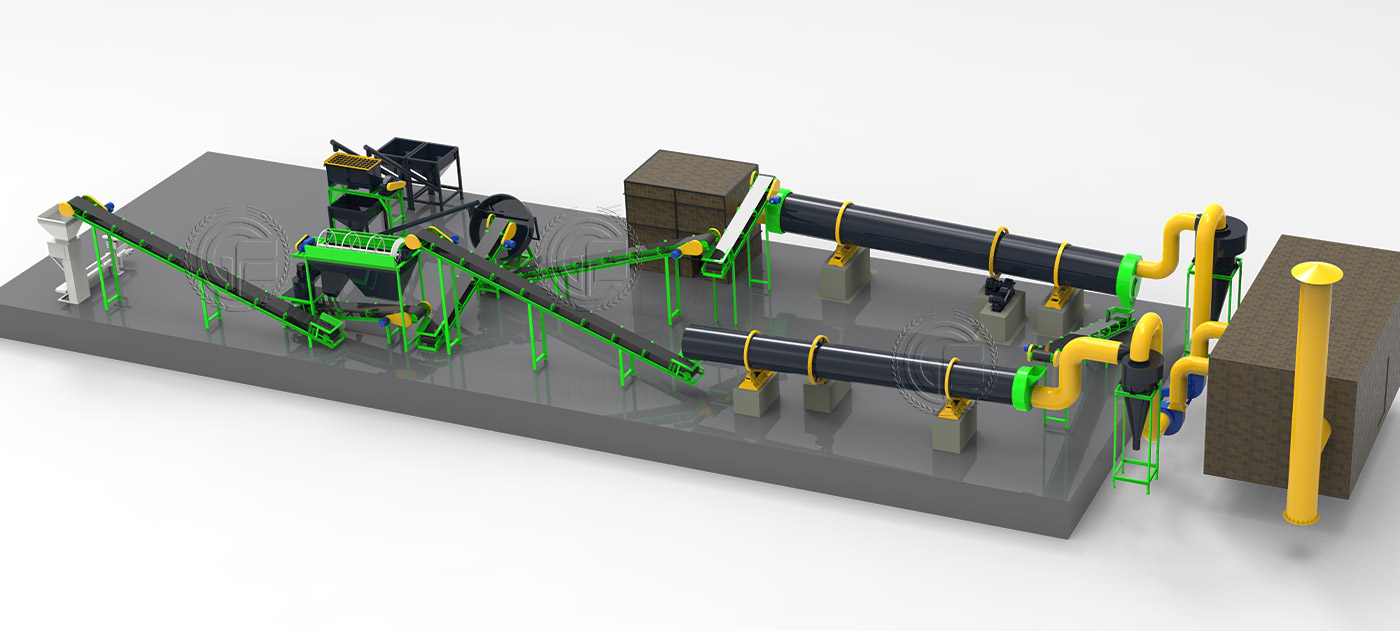

A disc granulation line uses a tilted, rotating disc to roll and agglomerate materials, gradually forming powdered or small particles into spherical granules. It features a simple structure, flexible operation, and excellent spherical granules.

Core Features

Excellent Spherical Shape: The material continuously rolls within the disc, resulting in nearly spherical granules with excellent fluidity, making them easy to package and use.

Flexible Operation: By adjusting the disc’s inclination, rotational speed, and water addition, the particle size and strength can be flexibly controlled to meet different product requirements.

Low Equipment Cost: Compared to extrusion granulation and fluidized bed granulation equipment, disc granulators offer a simple structure, low manufacturing costs, and a small footprint, making them suitable for small and medium-sized enterprises.

Highly adaptable: It can process powdered materials with moderate moisture content, especially those with moderate viscosity. With the addition of a binder, it can also process low-viscosity materials.

Low energy consumption: It does not require high-pressure extrusion or high-temperature melting. The main energy consumption comes from the disc drive and drying process, resulting in relatively economical operating costs.