The main types of chemical fertilizers include the following:

Nitrogen fertilizers: Nitrogen fertilizers provide plants with the nitrogen element needed for growth, promoting leaf growth and pigment synthesis. Common nitrogen fertilizers include urea and ammonium nitrogen fertilizers, such as ammonium sulfate and ammonium nitrate.

Phosphate fertilizers: Phosphate fertilizers provide plants with the phosphorus element needed for growth, promoting root development, flower bud differentiation, and fruit ripening. Common phosphorus fertilizers include diammonium phosphate, triammonium phosphate, and potassium dihydrogen phosphate.

Potassium fertilizers: Potassium fertilizers provide plants with the potassium element needed for growth, promoting root development, stress resistance, and fruit quality. Common potassium fertilizers include potassium chloride and potassium sulfate.

Compound fertilizers: Compound fertilizers contain multiple nutrients, providing nitrogen, phosphorus, and potassium simultaneously. Common compound fertilizers include nitrogen, phosphorus, and potassium compound fertilizers, such as granular and liquid fertilizers.

In addition to the above main chemical fertilizers, there are also other trace element fertilizers, such as boron fertilizers and zinc fertilizers, that provide the trace elements needed by plants.

These fertilizers play an important role in agricultural production. They provide the nutrients required by plants, promote plant growth and development, and thus increase crop yields and improve quality. Based on soil testing and crop needs, appropriate fertilizers can be selected for application.

Common Granulation Methods

Due to the different properties of inorganic fertilizer raw materials, different granulation methods are required. For example, ammonium dihydrogen phosphate is generally granulated using a wet method, suitable for a disc granulation line; potassium chloride is generally granulated using a dry method, suitable for an extrusion granulation line.

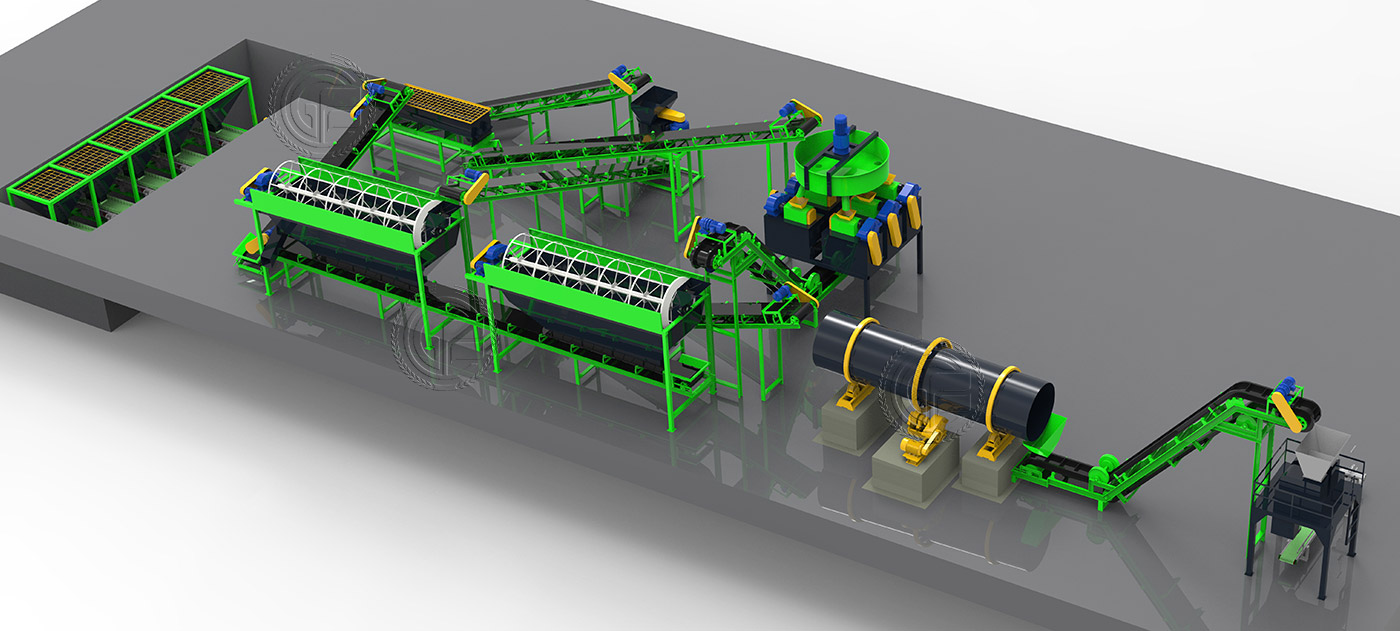

Extrusion Line

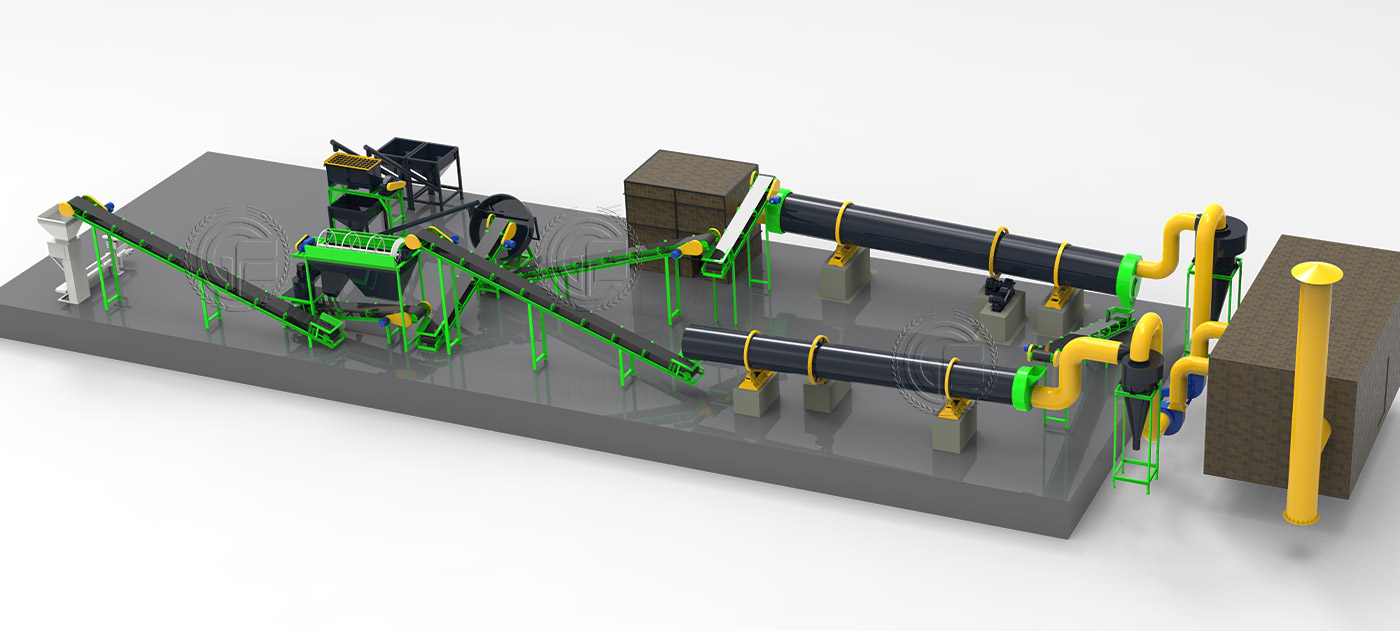

Disc Line

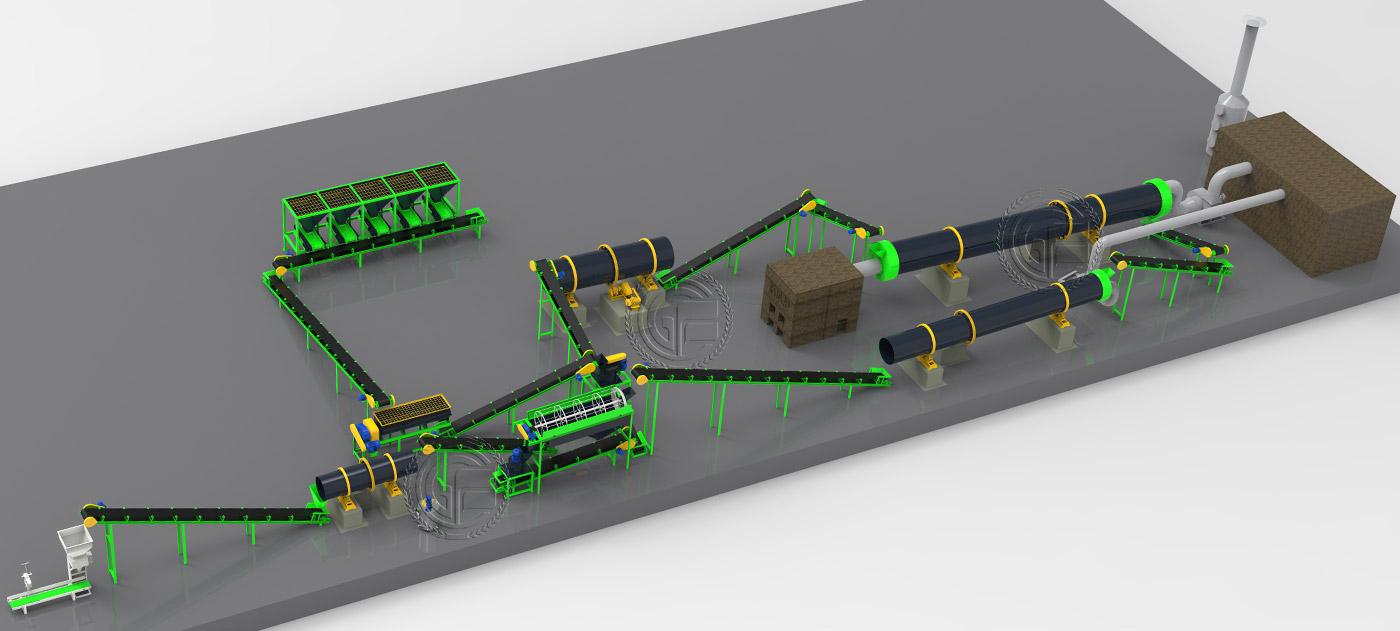

Drum Line

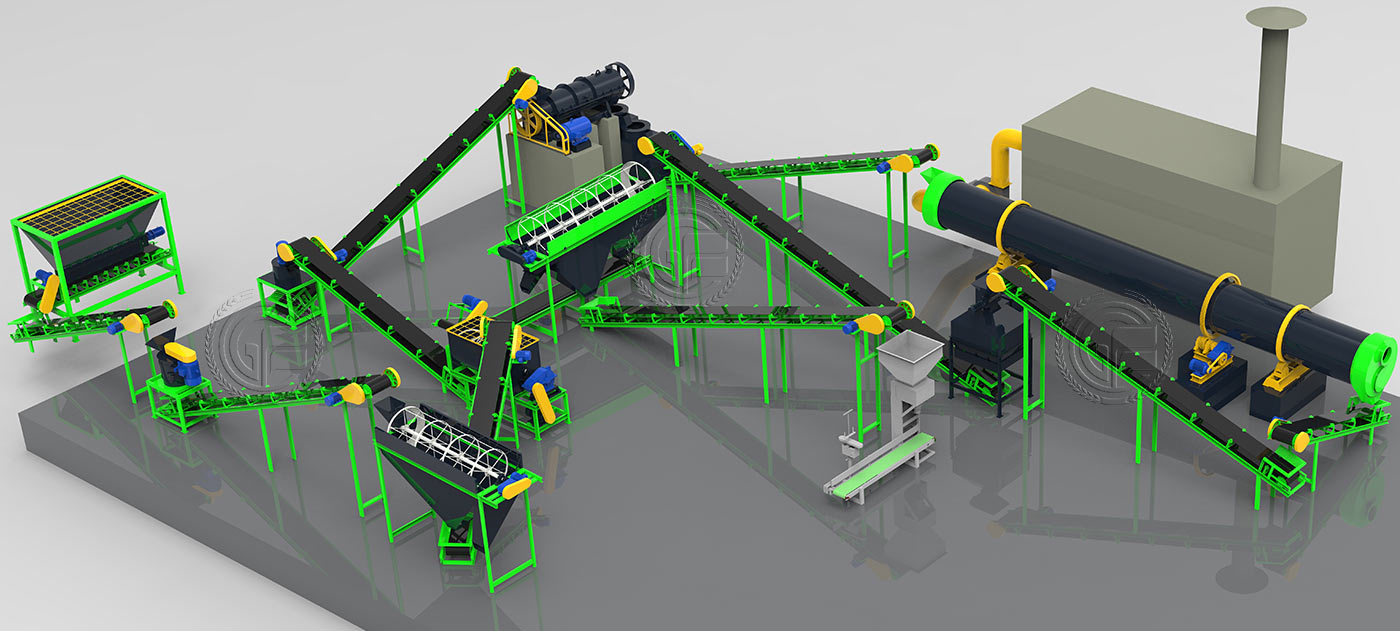

Agitator Line

Production Process

Raw material collection and pretreatment → Fermentation and decomposition → Crushing and screening → Ingredient mixing → Granulation → Drying and cooling → Screening and packaging

Features of inorganic fertilizers

High nutrient content and rapid results: Inorganic fertilizers have high nutrient concentrations and are mostly water-soluble, allowing them to be directly absorbed and utilized by crops. Rapidly increasing crop growth is observed shortly after application, making them suitable for critical growth periods when crops urgently need nutrients.

Single and controllable nutrient type for targeted application: Specific nutrients can be precisely provided based on crop needs. For example, applying potassium chloride to rice plants with potassium deficiency can quickly mitigate the risk of lodging. Complex formulas can also meet the diverse needs of crops.

Easy to use and store: Mostly in solid granule or powder form, they are easy to transport and apply. They are chemically stable, resistant to mold and rot, require minimal storage conditions, and have a long shelf life.

High purity and low impurities: Industrially purified, they are free of harmful substances such as pathogens, insect eggs, and weed seeds, reducing the risk of pests and diseases introduced by fertilizers.

Professional technical support

We provide full-process technical support, from material testing to equipment selection, to customize the most suitable granulation solution for you.

We provide precise equipment selection recommendations based on material characteristics and production capacity requirements to ensure maximum production efficiency.

We provide complete production line planning and design, from raw materials to finished product, to optimize processes, reduce energy consumption, and improve product quality.

Leave your message