NPK compound fertilizer, a widely used type of fertilizer in agricultural production, features a scientifically formulated combination of three core nutrients: nitrogen (N), phosphorus (P), and potassium (K). It provides comprehensive and balanced nutrient support for crop growth and is a key option for efficient fertilization in modern agriculture.

N refers to nitrogen fertilizer, which improves soil fertility, promotes plant growth, enhances photosynthesis, and increases chlorophyll content.

P refers to phosphorus fertilizer, which enhances plant resilience, promotes bud formation and flowering, strengthens stems and branches, and accelerates fruit ripening.

K refers to potassium fertilizer, which strengthens plant stems, enhances disease, insect resistance, and drought resistance, and improves fruit quality.

NPK compound fertilizers offer exceptional flexibility in their formulations. Manufacturers can customize their formulas based on soil fertility, climate conditions, and crop types in different regions.

Common Granulation Methods

NPK compound fertilizers place stringent demands on the compatibility of granulation equipment due to the raw material characteristics (nitrogen easily absorbs moisture, phosphorus easily agglomerates) and the finished product requirements (uniform granules and satisfactory strength). Currently, the mainstream granulation equipment in the industry includes disc granulators, rotary drum granulators, and extrusion granulators.

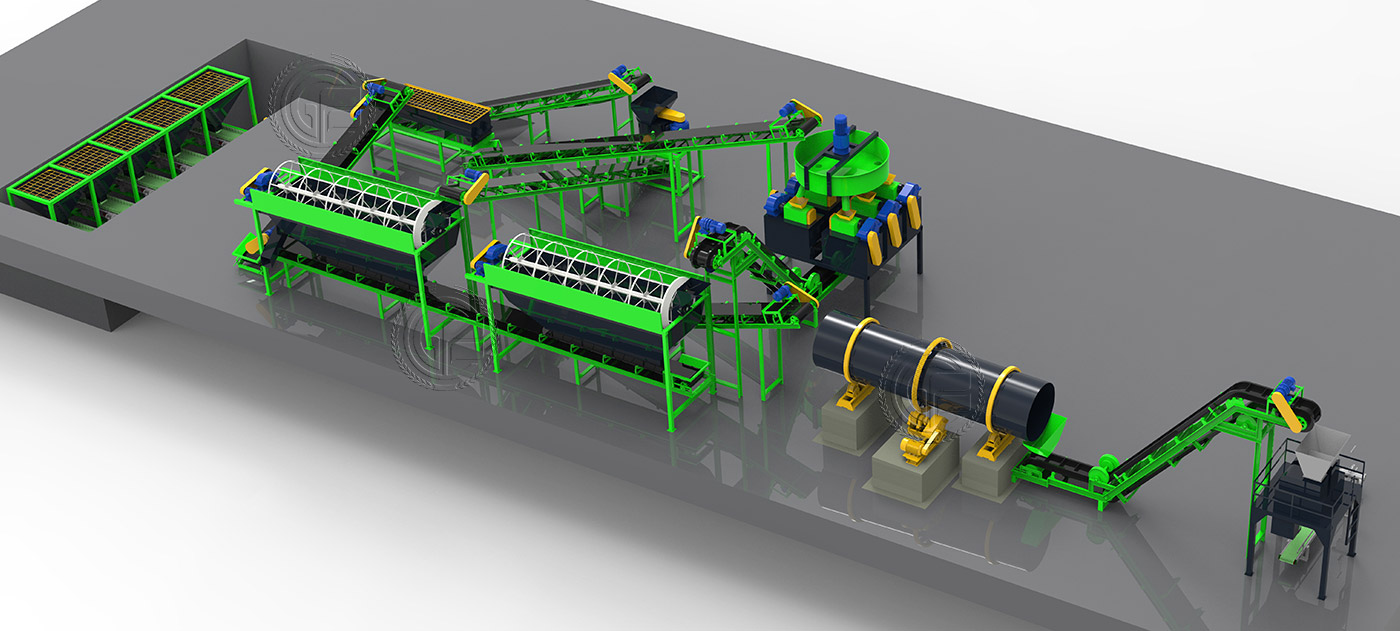

Extrusion Production Line

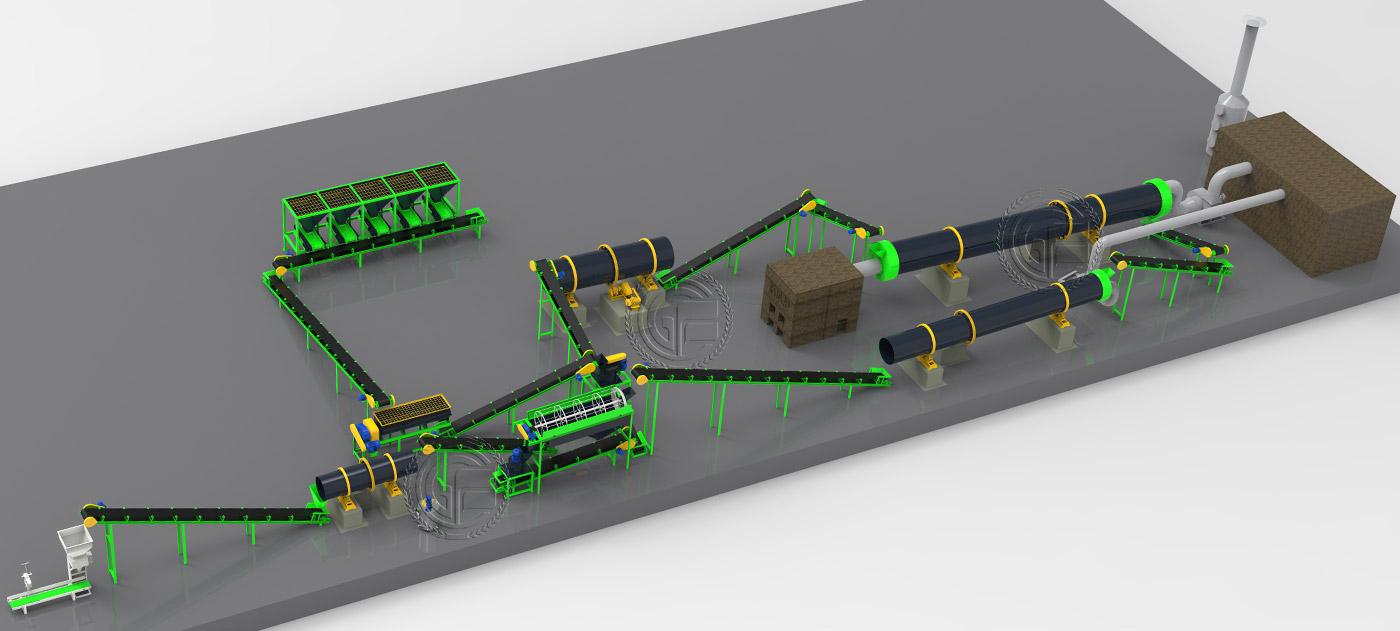

Disc Production Line

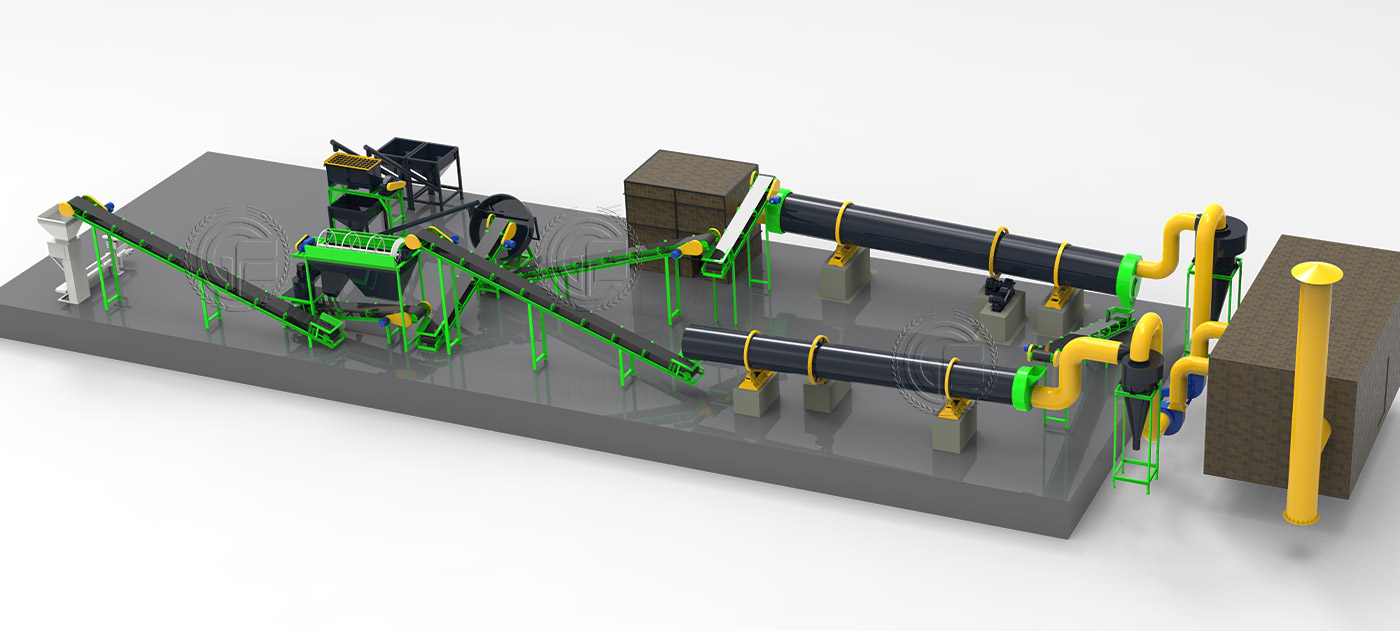

Drum Production Line

Production Process

Raw material collection and pretreatment → Crushing and screening → Ingredient mixing → Granulation → Drying and cooling → Screening and packaging

Features of NPK Fertilizer

Nutrient synergy and high efficiency: A scientifically formulated combination of nitrogen, phosphorus, and potassium avoids imbalances in individual elements, synergistically improving crop absorption efficiency and increasing yields by 10%-15% compared to a single fertilizer mix.

Convenient and labor-saving application: Granular fertilizers integrate multiple nutrients, meeting multi-stage needs with a single application, reducing fertilization frequency by 50% and increasing nutrient utilization to over 80%.

Flexible and adaptable formulas: Customizable according to crop type, soil characteristics, and growing period, covering fields, fruits, and vegetables, and addressing specific planting needs.

Stable Storage and Transportation Performance: Pellets boast a strength exceeding 8N, are resistant to breakage, and have low moisture absorption. They maintain no caking after 6 months of storage at 80% humidity, and their transportation loss rate is less than 3%.

Professional Technical Support

We provide comprehensive technical support, from material testing to equipment selection, to tailor the most suitable granulation solution for you.

We provide precise equipment selection recommendations based on material characteristics and production capacity requirements to ensure maximum production efficiency.

We offer complete production line planning and design, from raw materials to finished products, to optimize processes, reduce energy consumption, and improve product quality.

Leave your message