Flat die granulators are widely used in fertilizer and feed production. In fertilizer production, they can be used to granulate organic fertilizers, bio-organic fertilizers, and compound microbial fertilizers. They can process fermented organic raw materials such as livestock and poultry manure, straw, and medicinal residues, producing granulated fertilizers with stable fertilizer effects and easy application. In feed production, they are suitable for producing pelleted feed for livestock, poultry, and aquatic animals. They can process raw materials such as corn, soybean meal, and wheat bran into nutritionally balanced pellets, improving feed utilization.

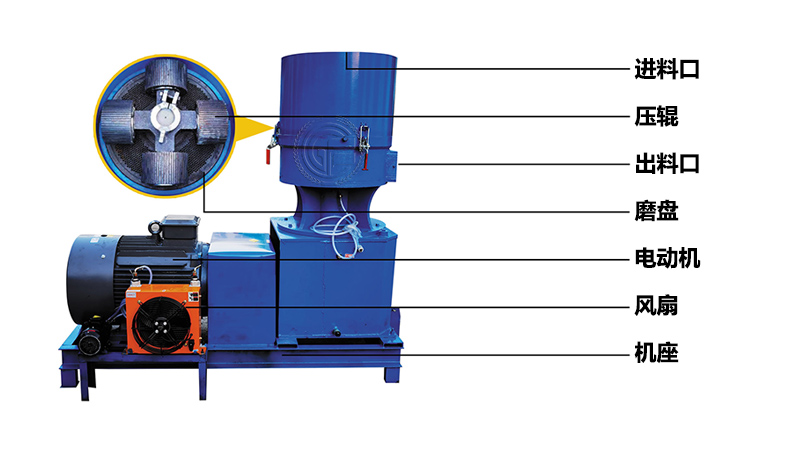

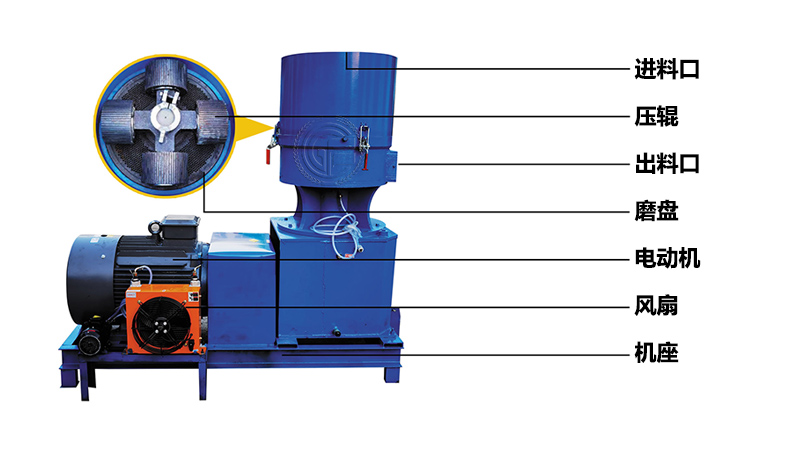

A flat die granulator mainly consists of a feeding mechanism, pressure roller assembly, flat die, transmission system, frame, and discharge mechanism.

Working principle

The flat die granulator operates based on the principle of extrusion granulation. Raw materials enter the gap between the flat die and the pressure rollers via the feeding mechanism. Driven by the transmission system, the pressure rollers press firmly against the surface of the flat die and rotate relative to it, forcing the raw material into the die holes under intense pressure. Within the die holes, the raw material is sheared and extruded, gradually taking shape and being extruded from the other end of the die hole to form columnar granules. These granules are then cut by a cutter mounted on the other side of the flat die, resulting in granules of uniform length.

Features

Simple structure: Fewer parts, compact layout, easy installation, operation, and maintenance, requiring less technical expertise from operators.

High adaptability: Can process a variety of raw materials, including organic materials with high moisture content, mixed fertilizers, and feed ingredients, especially suitable for materials containing fiber and straw.

High pellet quality: Produces high-density, high-hardness pellets that are not easily broken, facilitating storage and transportation. Pellet length can be controlled to meet diverse needs.

Flat die granulator components

Applications and Materials

Flat die granulators are among the most widely used equipment in the granulation field, especially when high-volume production is required.

Ammonium phosphate (MAP, DAP)

Ammonium sulfate

Biosolids

Compost and other organic materials

Manure (cattle, pigs, poultry)

Nitrogen, phosphorus, and potassium

Phosphate

Potassium fertilizer

Sulfur

Superphosphate

Urea

Picture