Liquid fertilizer, with its distinct form and properties compared to traditional solid fertilizers, offers significant advantages in providing crop nutrition.

Nutrients in liquid form can be directly absorbed by crop roots without dissolving, resulting in high absorption efficiency and rapid results. Liquid fertilizer can be mixed with most pesticides and growth regulators, reducing field work.

Common liquid fertilizer ingredients include inorganic salts such as urea, potassium nitrate, ammonium nitrate, potassium dihydrogen phosphate, phosphoric acid, and potassium sulfate, as well as organic substances such as humic acid, amino acids, and protein hydrolysates. These ingredients all have good solubility and nutrient content, allowing selection and formulation based on specific needs.

Common Manufacturing Methods

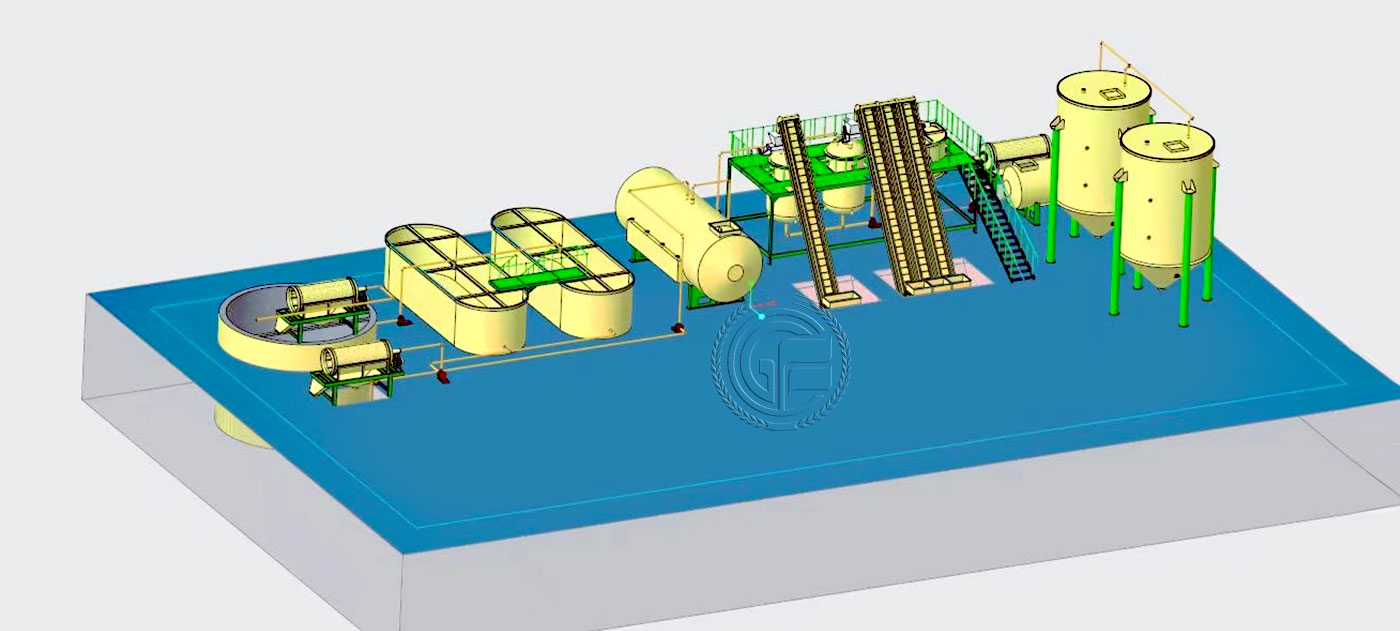

Liquid Fertilizer Production Line

Production Process

Raw Material Screening and Pretreatment → Nutrient Dissolution and Blending → Homogenization and pH Adjustment → Filtration and Sterilization → Testing, Filling, and Storage

Liquid Fertilizer Features

Fast Absorption and Effectiveness: Liquid nutrients require no dissolution and can be directly absorbed by crop roots or leaves.

Flexible Nutrient Ratio: The ratios of nitrogen, phosphorus, potassium, and trace elements can be precisely adjusted to meet the needs of crops at different growth stages.

Convenient and Versatile Application: It can be applied as a foliar spray or root irrigation, or integrated with drip or sprinkler systems for integrated water and fertilizer application.

Environmentally Friendly: Nutrients are evenly released, minimizing soil compaction and environmental pollution.

Professional Technical Support

We provide full-process technical support, from material testing to equipment selection, to customize the most suitable granulation solution for you.

We provide precise equipment selection recommendations based on material characteristics and production capacity requirements to ensure maximum production efficiency.

We provide complete production line planning and design, from raw materials to finished products, to optimize processes, reduce energy consumption, and improve product quality.

Leave your message