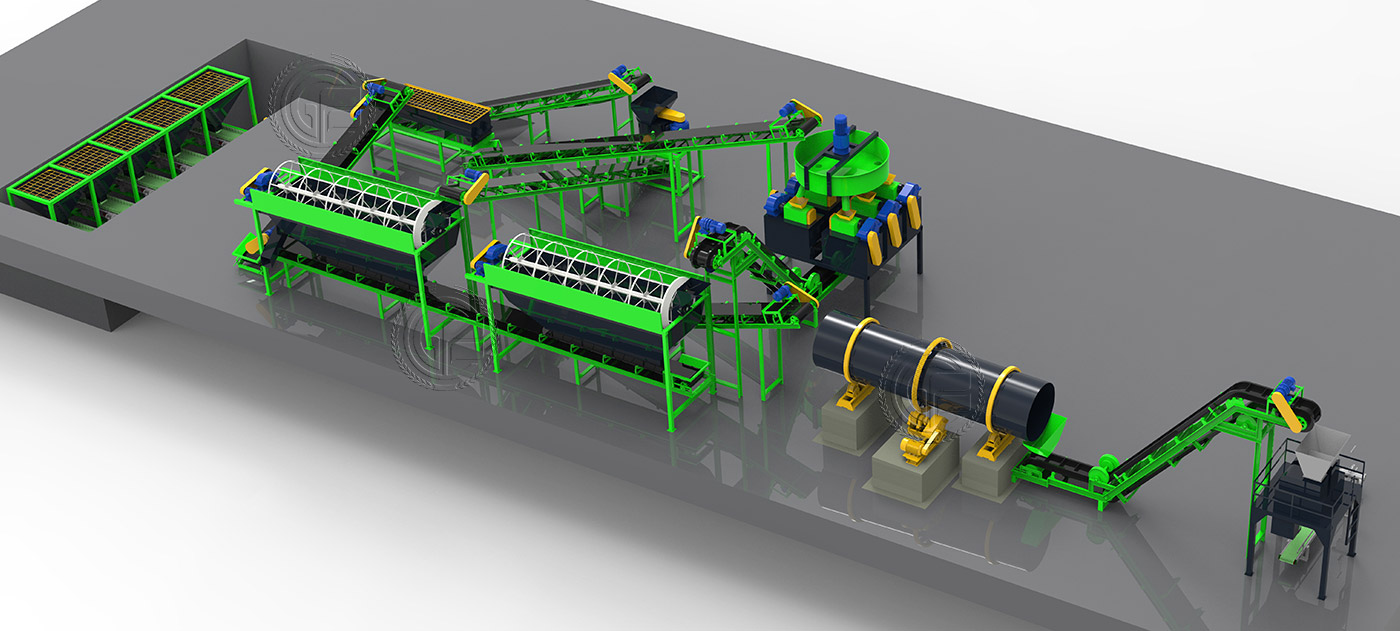

Extrusion granulation production line is a production line used to make granular products by extrusion molding of specific materials. It belongs to dry granulation technology. In the granulation process, only a small amount of water or no water is needed to granulate. Therefore, the subsequent production process can reduce the drying energy consumption. Some materials do not need to be dried after granulation.

Core Features

No Binder Required: Forming occurs solely through the material’s inherent plasticity or the friction between particles. This makes it particularly suitable for materials containing water of crystallization and prone to agglomeration (such as ammonium chloride and potassium sulfate), reducing production costs and avoiding secondary pollution.

Low Energy Consumption: Compared to processes such as melt granulation and spray granulation, double-roll extrusion does not require high-temperature heating, significantly reducing energy consumption.

High Adaptability: It can process powdered materials with low water content, including organic fertilizers, compound fertilizers, mineral powders, and chemical raw materials. By replacing rollers with different grooves, it can produce granules of various shapes and sizes.

High Pellet Strength: The material is fully compacted during the extrusion process, resulting in high density and hardness. These granules are resistant to moisture absorption and breakage, making them easy to store and transport.

Simple Process: Compared to other granulation processes, this eliminates complex steps such as melting and cooling, resulting in a simpler equipment structure, easier maintenance, and lower investment costs.