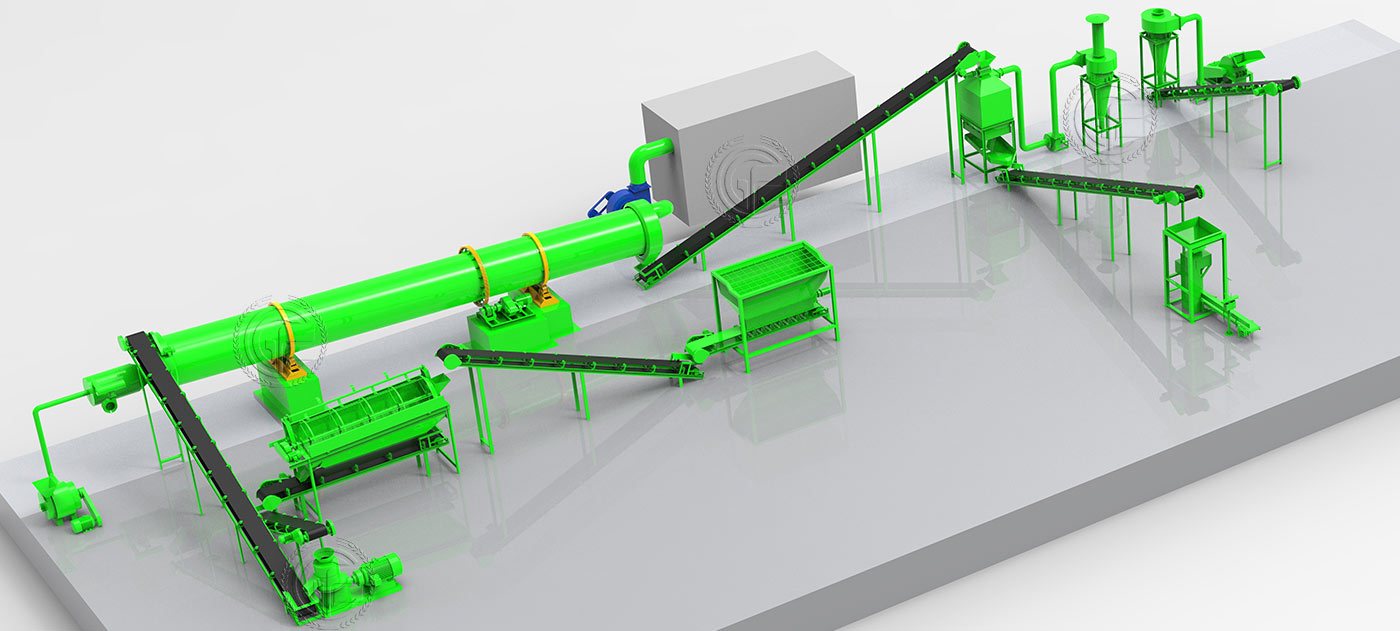

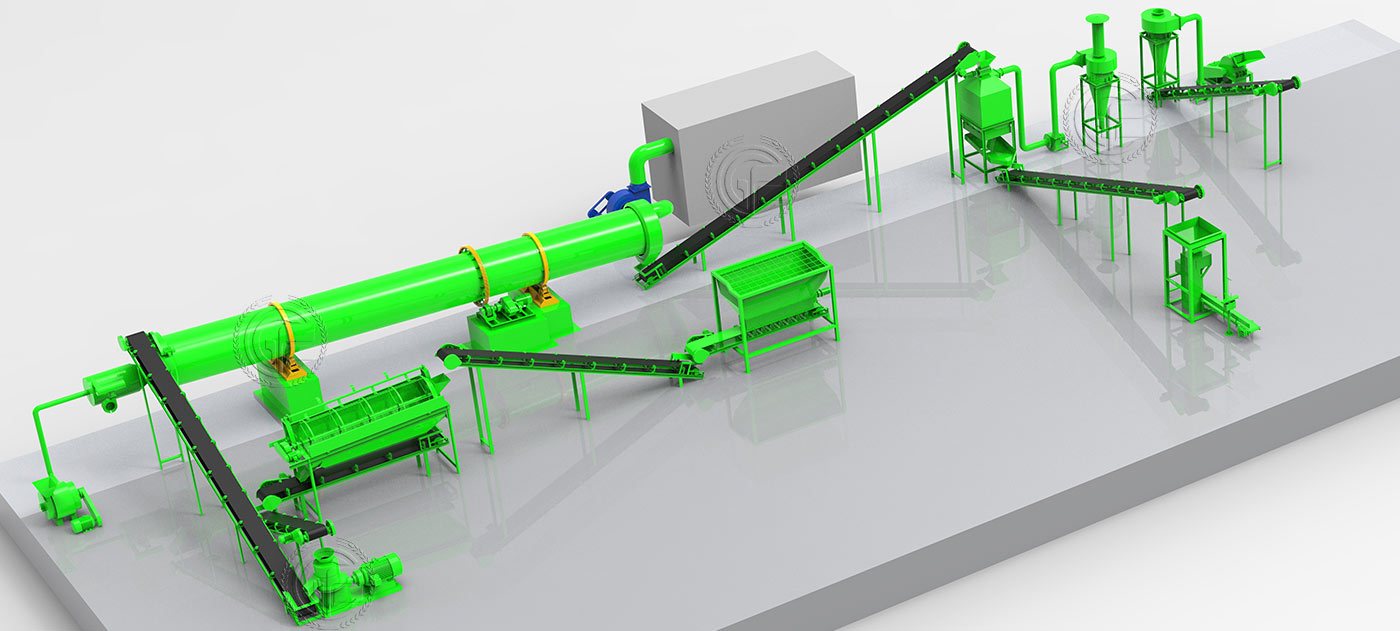

The flat die pelletizing line is an integrated production system centered around a flat die pelletizer, integrating raw material pretreatment, pelletizing, cooling, and screening. Designed for ease of operation and strong adaptability, it is widely used in the production of pellet products such as organic fertilizer, feed, and biomass fuel.

Core Features

Low-Operational Requirement: No complex commissioning is required; even beginners can master the process after a short training session. The equipment is easy to maintain, and consumable parts like the roller and flat die can be easily replaced, eliminating the need for specialized technicians.

Strong Adaptability: Quickly switch between production lines by simply changing the die hole and adjusting the raw material formula. It can produce a variety of products, including organic fertilizer, feed, and biomass pellets, meeting the needs of small-batch, multi-variety production.

More Controllable Costs: The overall equipment investment is low, and energy consumption is approximately 20% lower than other pelletizing lines, making it ideal for small and medium-sized businesses or startups with limited budgets. The process is streamlined and efficient: From raw material pretreatment and granulation to cooling and screening, the process is streamlined with few steps and a granulation rate exceeding 90%. Defective products can be returned for reprocessing, reducing waste.

Suitable for small and medium-sized operations: A single line has a production capacity of 0.5-2 tons, perfectly meeting the daily production needs of small and medium-sized organic fertilizer and feed plants, eliminating the need for overcapacity or undercapacity.