Disc granulators are widely used in fertilizer production and are core equipment for producing granular fertilizers such as organic fertilizers, compound fertilizers, and bio-fertilizers.

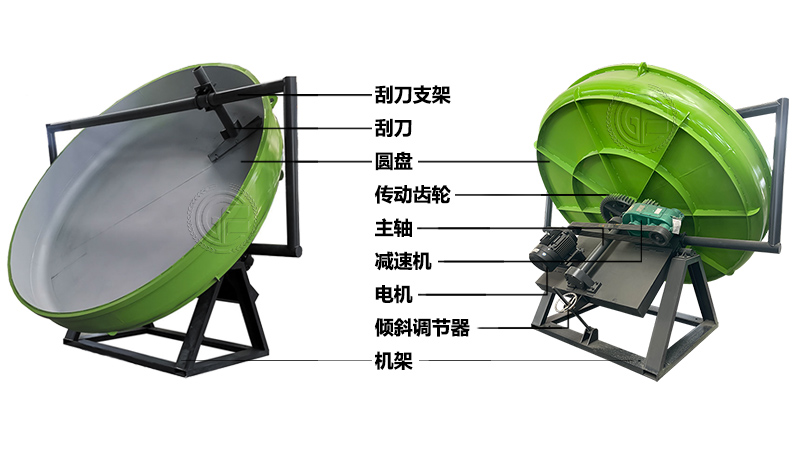

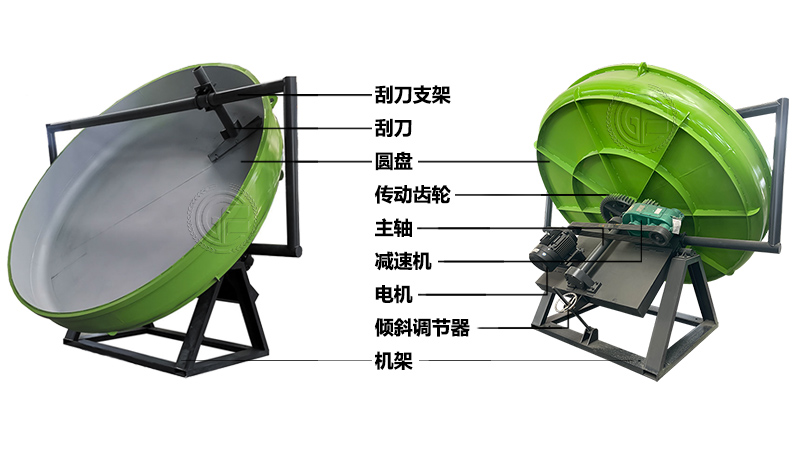

A disc granulator mainly consists of a granulation disc, a transmission system, a frame, an angle adjustment device, a material feeding device, and a water spraying system.

This equipment is also suitable for granulating powder materials in industries such as metallurgy and chemicals, such as metal powders, de-icing agents, and cat litter.

Working Principle

The disc granulator operates based on the principle of material agglomeration and granulation. The mixed raw materials are evenly fed into the rotating disc by the material feeding device. Driven by a motor, the disc rotates at a speed of 10-18 r/min. Under the combined action of centrifugal force, friction, and gravity, the material rolls upwards along the bottom of the disc. Simultaneously, the water spraying system sprays an appropriate amount of atomized water onto the material, wetting the surface of the raw material particles and creating stickiness. During the rolling process, the particles continuously adsorb surrounding fine particles, gradually forming spherical particles.

Features

Superior Granulation Quality: Granules are spherical with high roundness, smooth surface, and good flowability, facilitating subsequent screening, packaging, and application. Granulation rate can reach over 90%.

Flexible Operation: Disc rotation speed, tilt angle, and water spray volume can all be independently adjusted, quickly adapting to different raw material characteristics and easily controlling granule size and hardness to meet diverse production needs.

Strong Adaptability Can process materials with high moisture content (20%-30%), has low requirements for raw material purity, and can adapt to the granulation needs of organic, inorganic, and mixed fertilizers.

Disc Granulator Components

Applications and Materials

Disc granulators are among the most widely used equipment in the granulation field, especially when high-volume production is required.

Ammonium Phosphate (MAP, DAP)

Ammonium Sulfate

Biosolids

Compost and Other Organic Materials

Manure (Cattle, Pigs, Poultry)

Nitrogen, Phosphorus, Potassium

Phosphate

Potassium

Sulfate

Superphosphate

Urea

Images