Deicing agent granules are granular snow removal products produced through a specialized granulation process. Their optimized form significantly improves ease of use, performance stability, and environmental friendliness compared to traditional powdered deicing agents, making them a mainstream choice for modern snow removal operations.

Deicing agents are primarily categorized into two types: chloride-based deicing agents (such as sodium chloride, calcium chloride, and magnesium chloride) and non-chloride-based deicing agents (such as potassium acetate and propylene glycol).

Common Granulation Methods

Most deicing agent granules are irregularly spherical or cylindrical, 2-5 mm in diameter, with a smooth surface and moderate hardness. This structure is typically derived from the extrusion granulation process.

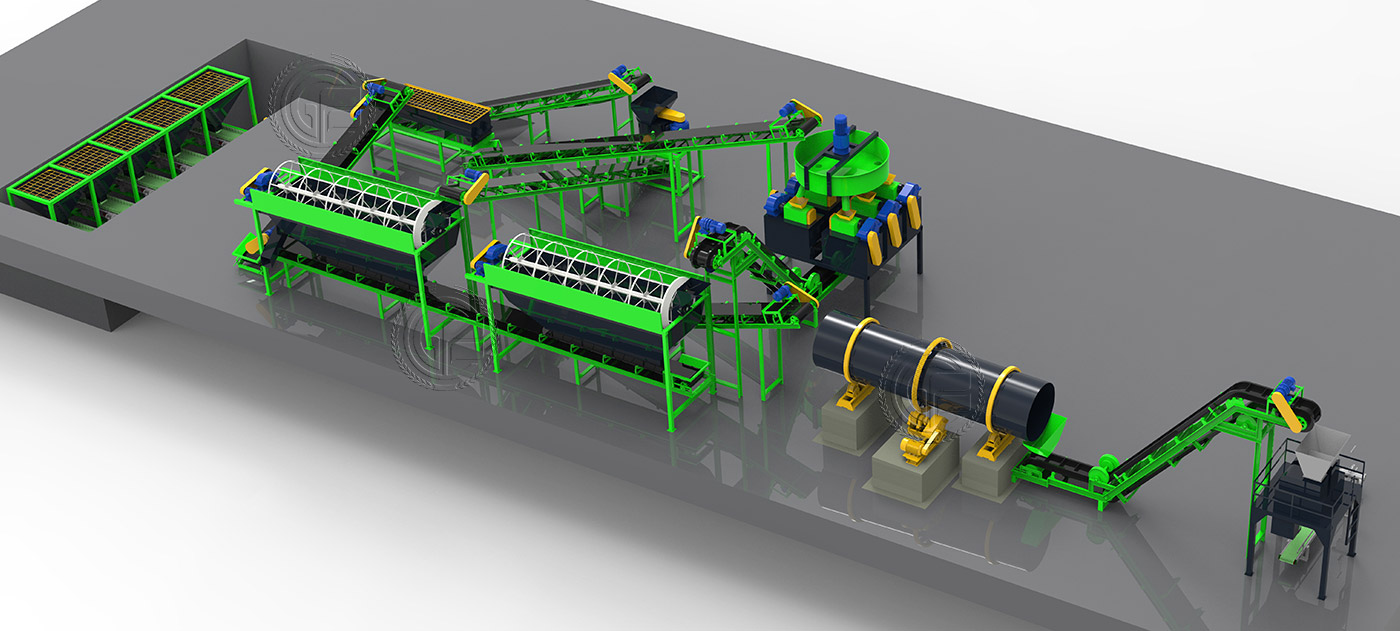

Extrusion Production Line

Production Process

Raw material collection and pretreatment → Fermentation and decomposition → Crushing and screening → Ingredient mixing → Granulation → Drying and cooling → Screening and packaging

De-icing agent features

Fast and efficient snow melting: Rapidly lowers the freezing point of ice and snow, taking effect in 30 minutes at -5°C, and clearing over 50% of accumulated snow in 1-2 hours.

Widely applicable: Can be spread manually or mechanically, suitable for roads, airports, and other locations, and supports pre-spreading to prevent freezing.

Significant cost differences: Chloride salts are inexpensive and suitable for large-scale use, while environmentally friendly salts are more expensive but less corrosive. Choose according to your needs.

A balance must be struck between environmental protection and environmental performance: Excessive use can have ecological impacts. Currently, low-dose, scientific spreading and the use of synergists are more commonly used to minimize these risks.

Professional Technical Support

We provide comprehensive technical support, from material testing to equipment selection, to tailor the most suitable granulation solution for you.

We provide precise equipment selection recommendations based on material characteristics and production capacity requirements to ensure maximum production efficiency.

We provide comprehensive production line planning and design, from raw materials to finished products, to optimize processes, reduce energy consumption, and improve product quality.

Leave your message