The stirring tooth granulator is widely used in fertilizer production and is a key granulation equipment in organic fertilizer, compound fertilizer, and bio-fertilizer production lines.

The stirring tooth granulator is based on a “stirring and granulation chamber + high-speed stirring tooth assembly,” and is composed of a motor, gearbox, rotor, cylinder, and frame.

The entire equipment consists of five core systems, with each component working in tandem to ensure that raw materials are quickly agglomerated into high-quality granules.

Working Principle

The stirring tooth granulator utilizes the mechanical stirring force of high-speed rotation and the resulting aerodynamics to continuously mix, granulate, ball, and densify fine powder materials within the machine, thereby achieving the purpose of granulation.

Features

Excellent granulation effect: Through high-speed stirring and extrusion by the stirring teeth, the granules have high density and strength, with a stable balling rate exceeding 85%. It can produce granules of 2-8mm, solving the problems of “low balling rate and loose granules” found in traditional equipment. **Flexible Capacity Adaptability:** With a single unit processing capacity of 1-5 tons per hour, it can meet the needs of small and medium-sized fertilizer plants as well as large-scale agricultural input enterprises, eliminating the need for frequent equipment replacements due to capacity adjustments.

Versatile and Widely Adaptable:

By adjusting the speed of the stirring teeth and the temperature of the granulation chamber, it can be adapted to granulate various types of fertilizers, including organic fertilizers, compound fertilizers, and bio-fertilizers, reducing equipment investment costs.

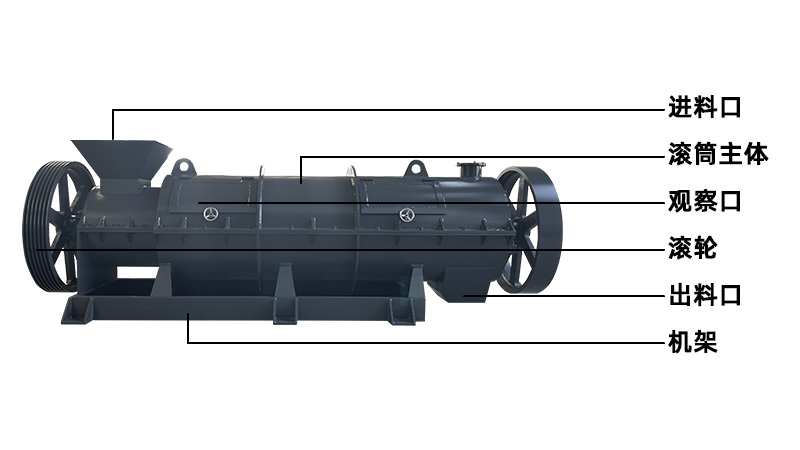

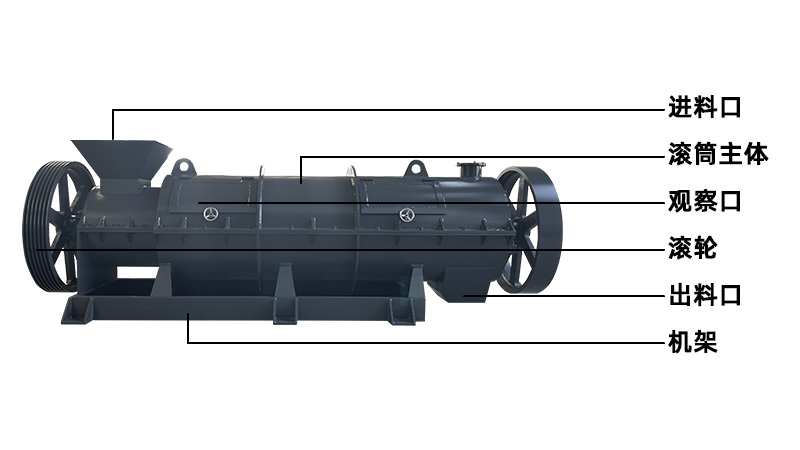

Double Roller Extrusion Granulator Components

Applications and Materials

The double roller extrusion granulator is one of the most widely used pieces of equipment in the granulation field, especially when high output is required.

Ammonium phosphate (MAP, DAP)

Ammonium sulfate

Biosolids

Compost and other organic materials

Manure (cattle, pigs, poultry)

Nitrogen, phosphorus, potassium

Phosphate

Potassium fertilizer

Sulfur

Superphosphate

Urea

Image