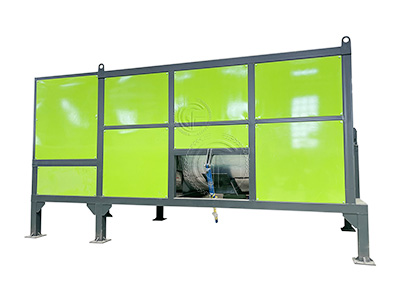

The horizontal fermentation tank for organic fertilizer is the core equipment for the composting of organic raw materials such as livestock and poultry manure, straw, and microbial residue.

Organic raw materials are put into the tank, and the stirring paddle continuously turns the material to ensure uniform contact with oxygen; the temperature control system stabilizes the temperature inside the tank within the optimal range for microbial activity, accelerating the decomposition of organic matter.

Product Features:

High composting efficiency: The sealed temperature control design stabilizes the temperature inside the tank within the 55-65℃ microbial activity range, shortening the natural composting cycle from 20-30 days to 7-10 days, increasing efficiency by more than 60%.

Good environmental performance: The fully enclosed tank, equipped with a deodorization device, reduces the emission of odors such as hydrogen sulfide, avoiding environmental pollution and meeting environmental standards.

High adaptability: Adjustable stirring speed and ventilation volume enable the processing of various organic raw materials such as livestock and poultry manure and straw with a moisture content of 50%-65%, preventing clumping or incomplete decomposition.

Image