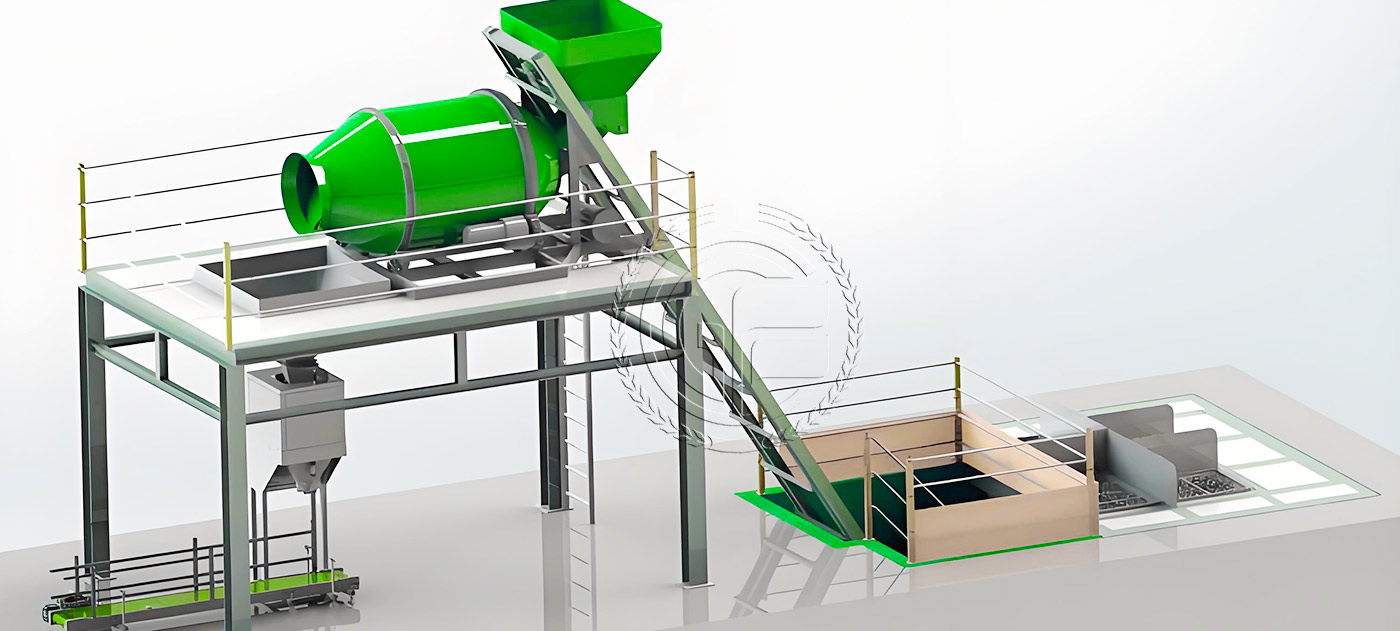

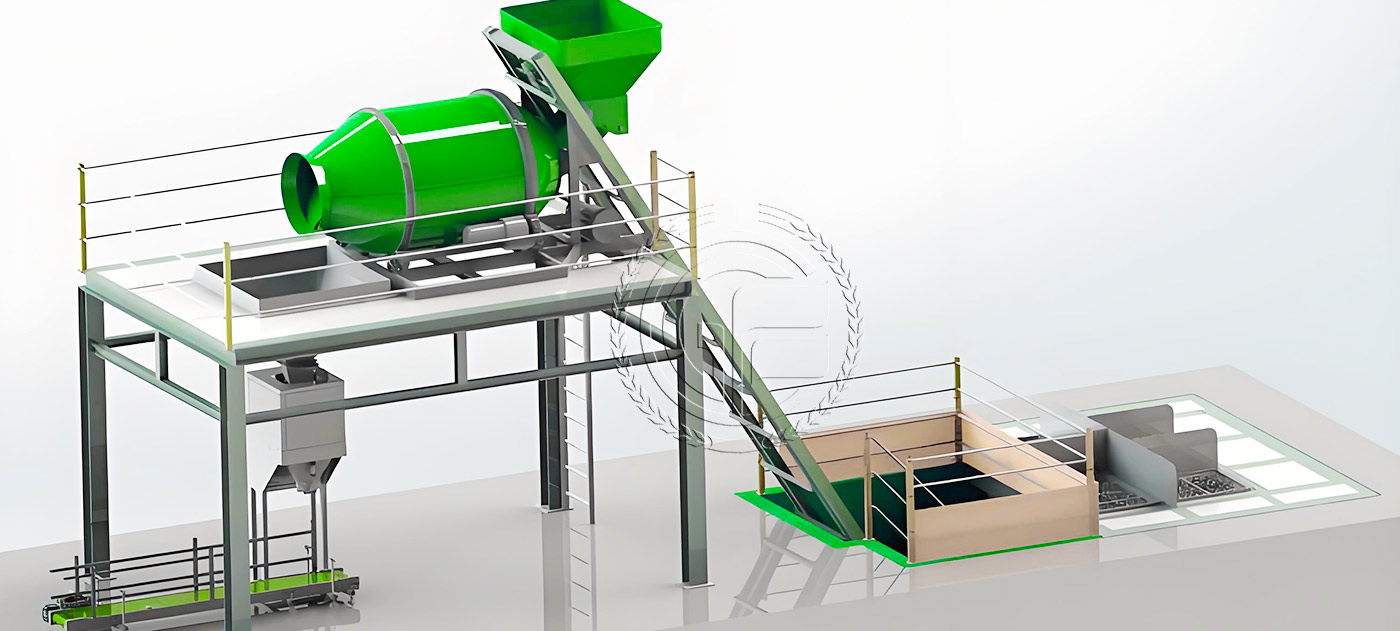

The BB fertilizer production line is a specialized production system designed for blended fertilizers. It integrates raw material storage, precise batching, efficient mixing, and automatic packaging. It can precisely blend multiple single fertilizers into customized formulas to meet the nutrient requirements of different crops and soils.

Core Features

Flexible Production: Supports rapid switching between multiple recipes. By calling preset recipes through the PLC system, the transition from one recipe to another can be completed within 15 minutes, meeting both small and multi-batch production needs.

Intelligent Management and Control: Equipped with an industrial-grade control system, it monitors key parameters such as raw material remaining level, batching accuracy, and mixing time in real time. It also supports remote diagnostics and data traceability, ensuring a stable and controllable production process.

Particle Protection Design: The mixing equipment utilizes a low-speed, non-shearing structure to minimize raw material particle breakage (≤3%), ensuring the integrity and fluidity of the finished fertilizer particles, facilitating subsequent application.

Environmental Protection and Energy Saving: The entire system operates in a closed-loop system and is equipped with a dust collection device, achieving a dust emission concentration of ≤8mg/m³. The power system utilizes variable frequency control, reducing energy consumption by 15% compared to traditional production lines.