Voltage: 380v

Power: 11-15kw

Particle size range: 3-10mm

Balling rate: ≥95%

Output: 1-3t/h

Raw materials: feces, straw, sludge, etc.

Products support customization, please contact us if necessary

Sales Hotline:+8615138666240

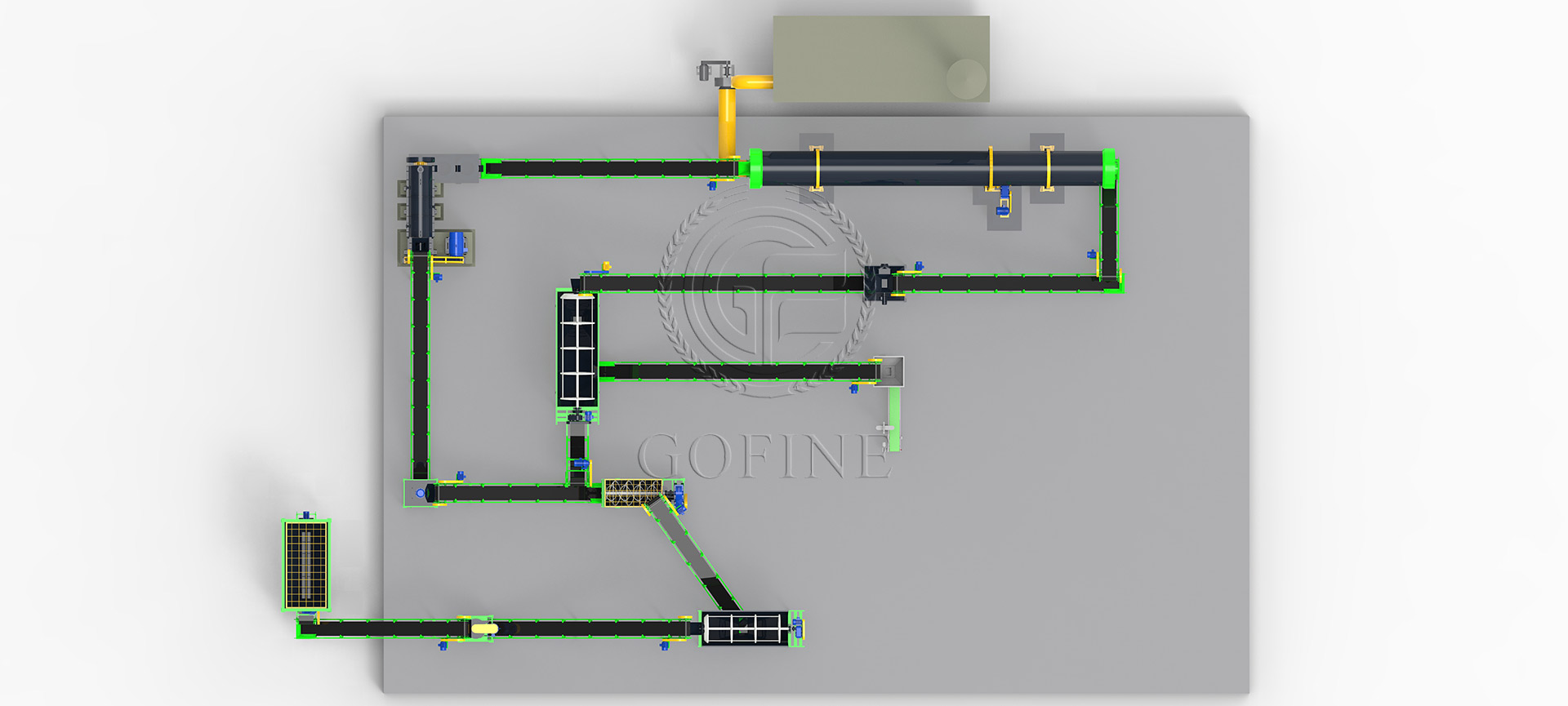

The organic fertilizer granulation production line is a combination of equipment that processes organic waste into granular organic fertilizer. It is a complete system that integrates high technology and fine technology. The process is closely linked and has significant economic and environmental benefits. The production line usually includes the main process of raw material collection, fermentation, crushing, batching, mixing, granulation, drying, packaging, etc.

1. Raw material collection and pretreatment: Collect fresh organic waste (such as livestock and poultry manure, agricultural waste, etc.) and reduce its moisture content by dehydration, drying, etc.

2. Fermentation and decomposition: Mix the pretreated materials with microbial fermentation agents evenly, pile them in a fermentation tank or fermentation pool, and turn the pile regularly to ensure full fermentation and decomposition.

3. Crushing and screening: The fermented and decomposed materials are crushed by a crusher to obtain fine powder with uniform particle size.

4. Batching and mixing: The sieved fine powder is batched with auxiliary materials such as trace elements, humic acid, clay, etc., and mixed evenly with a mixer.

5. Granulation: The mixed materials are granulated using a fertilizer granulator to obtain granular organic fertilizer that meets the requirements.

6. Drying and cooling: The granulated particles are sent to a dryer for drying. Then a cooler is used to cool the dried particles.

7. Screening and packaging: The dried and cooled particles are screened again by a screening machine. Finally, an automatic packaging machine is used to quantitatively package the qualified particles.

1. Wide adaptability of raw materials: Organic fertilizer production lines can process a variety of organic raw materials, such as livestock and poultry manure, crop straw, green manure, biogas residue, sludge and other organic waste.

2. Process diversity: Organic fertilizer production lines use a variety of processes, including composting and fermentation.

3. Controllable product quality: The production line can adjust the nutrient content of organic fertilizer according to different soil and crop requirements.

4. Significant economic benefits: Through the production and sale of organic fertilizers, agricultural producers can obtain additional economic benefits.

5. Promote sustainable agricultural development: Organic fertilizer production lines can convert agricultural waste into valuable organic fertilizers.

The professional after-sales team is on call at any time. Once you encounter any problems during the installation and commissioning of the equipment, they will rush to the site as soon as possible and use their superb technology to ensure the smooth start-up and operation of the production line. In the subsequent daily production, if the equipment fails, just one phone call and the after-sales staff will respond within 24 hours, quickly diagnose the problem and provide a solution. Regular equipment maintenance services are even more indispensable. The after-sales team will develop a personalized maintenance plan based on your production situation, conduct a comprehensive “physical examination” for the equipment on site, replace wearing parts, and ensure that the production line is always in the best operating condition. In addition, we also provide customers with operation training services, so that your employees can quickly become familiar with the equipment operation process, master basic maintenance knowledge, and reduce problems caused by improper human operation.