The material is placed in the rotating pot and tumbles as the pot rotates. The coating liquid is sprayed evenly on the surface of the tumbling material through a spray gun, and at the same time, the hot air system sends hot air into the pot to quickly evaporate the solvent in the coating liquid, and the coating material forms a thin film on the surface of the material.

Products support customization, please contact us if necessary

Sales Hotline:+8615138666240

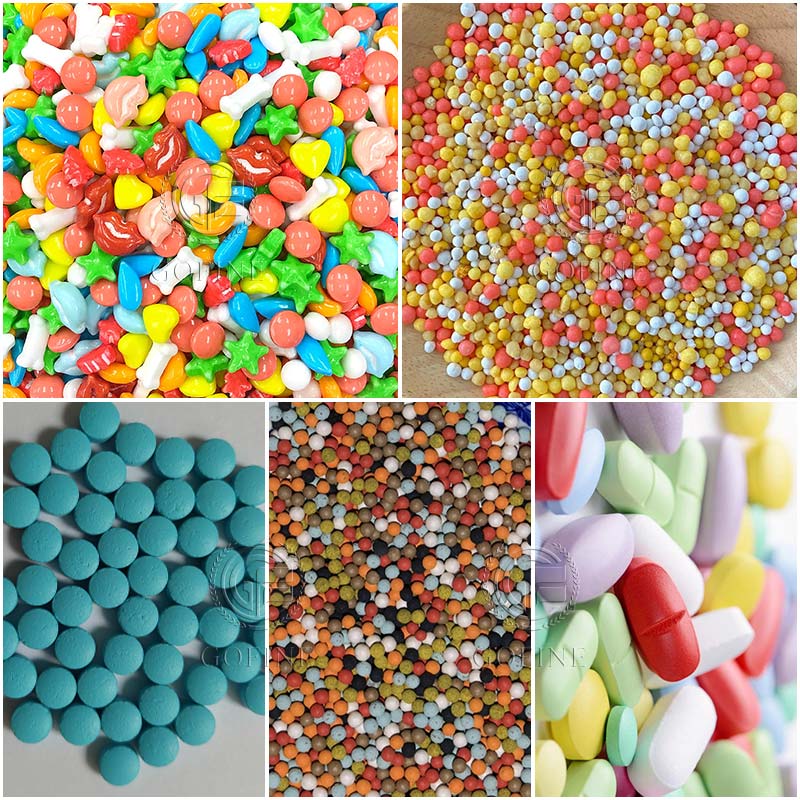

Stainless steel coating machine is a kind of equipment for coating tablets, pills, candies, etc. It is mainly used to coat a layer of sugar coating, film coating and other materials on the surface of granular objects such as drugs or foods, which plays a variety of functions such as protection, taste masking, and drug release control. For example, in the pharmaceutical industry, many drugs need to be coated to prevent the drugs from being destroyed by gastric acid in the stomach, or to make the drugs easier to swallow; in the food industry, coating can make candies and other products more attractive and extend their shelf life.

Machine body: The whole machine is made of stainless steel, which has good corrosion resistance, is easy to clean, and meets the hygiene requirements of pharmaceutical and food production. Stainless steel can ensure that the machine will not rust during long-term use, and prevent impurities such as rust from mixing into the product.

Pot body: The pot body of the coating machine is the core component, and its shape is usually water chestnut-shaped or pear-shaped. This shape design helps the material to tumble in the pot, making the coating process more uniform. The speed of the pot body can be adjusted according to different products and coating requirements, and is generally controlled by motors and transmission devices.

Spray gun system: includes spray gun, spray pipe and pressure regulating device. The quality of the spray gun directly affects the coating effect, and it can spray the coating liquid evenly on the surface of the material. The spray pipe needs to ensure the stability of liquid delivery and is easy to clean.

Hot air system: It is mainly composed of heaters, fans and ventilation ducts. The hot air system is used to provide the hot air required for drying, so that the coating liquid can be quickly dried after being sprayed on the surface of the material to form a uniform coating film.

Stainless steel coating machine Can be used for special applications in the pharmaceutical industry, innovative applications in the food industry

The material is placed in the rotating pot and tumbles as the pot rotates. The coating liquid is sprayed evenly on the tumbling material surface through a spray gun, and at the same time, the hot air system sends hot air into the pot, so that the solvent in the coating liquid evaporates quickly, and the coating material forms a thin film on the surface of the material. This process is a continuous dynamic process. By continuously spraying the coating liquid and drying with hot air, the thickness of the coating film is gradually increased until the desired coating effect is achieved. For example, in the film coating process, the film-forming materials in the coating liquid, such as hydroxypropyl methylcellulose, are dried and solidified under the action of hot air, forming a smooth and uniform film on the surface of the drug tablet.

Excellent hygienic performance, the stainless steel surface is smooth and easy to clean and disinfect.

Strong durability, the stainless steel material itself has good corrosion resistance,

Good temperature and chemical stability, stainless steel can maintain stable physical properties in a wide temperature range and will not deform or damage due to temperature changes