Voltage: 380v

Power: 11-15kw

Particle size range: 3-10mm

Balling rate: ≥95%

Output: 1-3t/h

Raw materials: phosphate ore, potash ore, boron ore

Products support customization, please contact us if necessary

Sales Hotline:+8615138666240

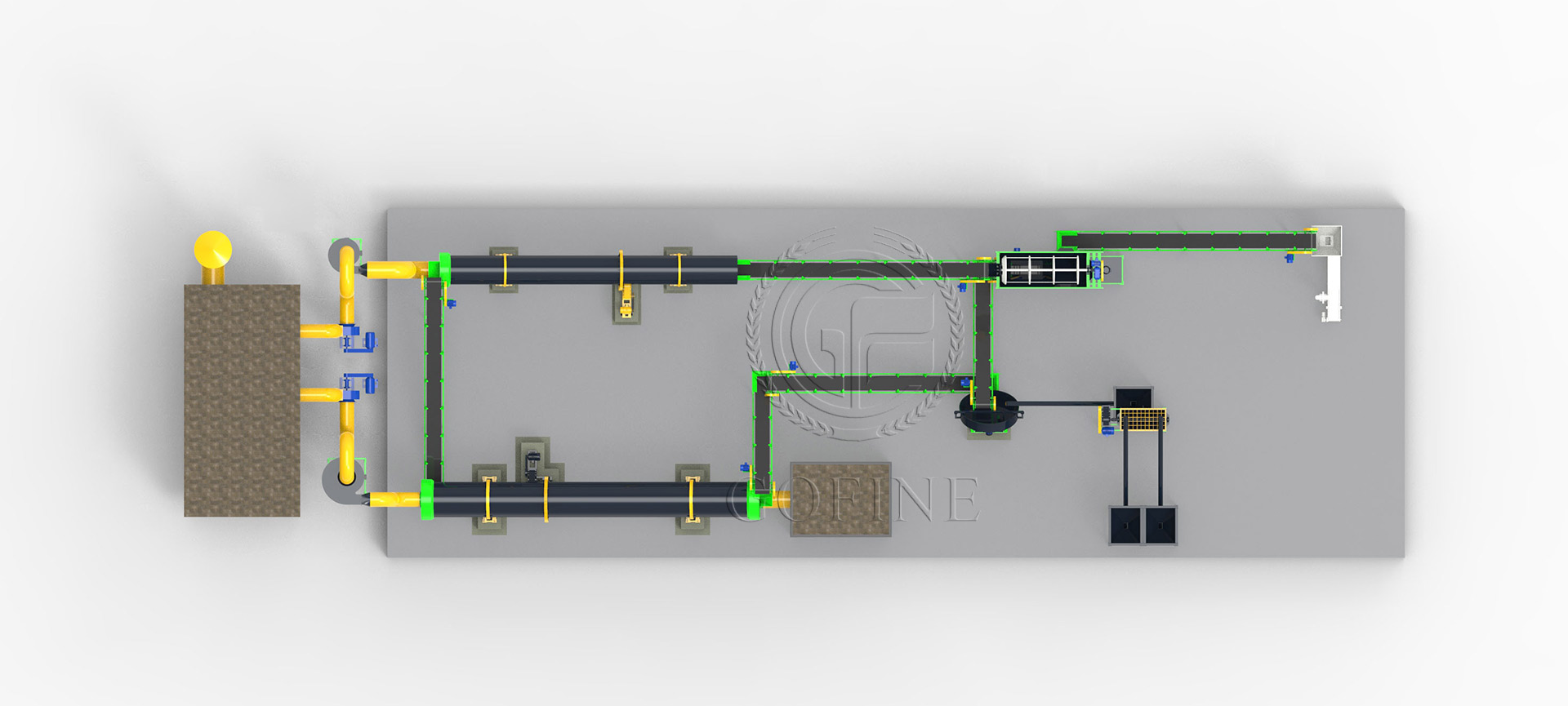

The mineral fertilizer granulation production line is a series of equipment combinations used to process mineral fertilizer raw materials into granular products. The production line usually includes the main processes of raw material pretreatment, mixing, granulation, drying, cooling, screening, coating and metering packaging. First, the mineral raw materials are pretreated by crushing and grinding to achieve a certain fineness and uniformity; then different raw materials are mixed according to the formula; then the mixed materials are made into granules by using appropriate granulation equipment; then the granules are dried and cooled to remove moisture and reduce the temperature; then the granules are graded and screened by screening equipment, and qualified granules enter the coating process, and finally metering and packaging are carried out to obtain the finished product.

1. Raw material preparation: Select appropriate mineral raw materials, such as phosphate rock, potash ore, boron ore, etc., and pre-treat them.

2. Ingredient mixing: Add various mineral raw materials and auxiliary raw materials to the mixing equipment in a certain proportion for full mixing.

3. Granulation: Send the evenly mixed materials into the granulation equipment for granulation operation to form granular mineral fertilizers.

4. Drying: The fertilizer particles after granulation usually contain a certain amount of moisture and need to be dried by drying equipment.

5. Screening: The dried fertilizer particles are screened by screening equipment.

6. Cooling: The temperature of the granular fertilizer after drying and screening is high and needs to be cooled.

7. Coating: The cooled particles are coated, that is, a thin layer of coating material, such as resin, paraffin, etc., is wrapped on the surface of the particles.

8. Packaging: Finally, the coated granular fertilizer is packaged according to the specified weight and packaging form.

1. High product quality: the particles are regular and uniform in size, which makes storage and transportation more convenient, and can effectively reduce breakage and loss during handling and storage. Moreover, its slow-release performance can make the fertilizer nutrients release slowly and lastingly, greatly improve the fertilizer utilization rate, and provide longer-lasting nourishment for crops.

2. High production efficiency: advanced granulation equipment has strong adaptability and high particle strength. The equipment for drying and cooling processes can also work efficiently to ensure the efficient operation of the production line.

3. Strong adaptability: It can perfectly adapt to mechanized fertilization equipment, which can greatly improve fertilization efficiency and reduce labor intensity.

4. Good after-sales service: Professional after-sales team accompanies the whole process from the first day of equipment installation, and installation and commissioning problems can be solved on site immediately. Sudden failures in daily production will be responded to within 24 hours.

The professional after-sales team is on call at any time. Once you encounter any problems during the installation and commissioning of the equipment, they will rush to the site as soon as possible and use their superb technology to ensure the smooth start-up and operation of the production line. In the subsequent daily production, if the equipment fails, just one phone call and the after-sales staff will respond within 24 hours, quickly diagnose the problem and provide a solution. Regular equipment maintenance services are even more indispensable. The after-sales team will develop a personalized maintenance plan based on your production situation, conduct a comprehensive “physical examination” for the equipment on site, replace wearing parts, and ensure that the production line is always in the best operating condition. In addition, we also provide customers with operation training services, so that your employees can quickly become familiar with the equipment operation process, master basic maintenance knowledge, and reduce problems caused by improper human operation.