Release time:December 6, 2024

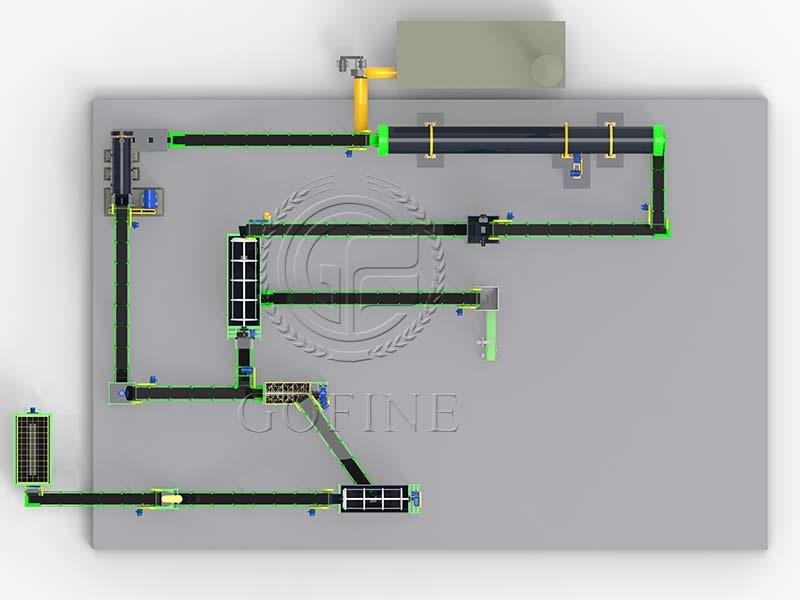

I. Overview of the Production Line

The new gear drum granulator production line is an efficient fertilizer production system that integrates modern mechanical design, automatic control, and refined chemical technology. It has revolutionized the traditional granulation method. With its unique gear drum structure and advanced process combination, it accurately controls every link from raw material processing to finished product packaging. It is suitable for the production of multiple types of fertilizers such as compound fertilizers, organic fertilizers, and biological fertilizers, which meets the current strong demand for high-quality, granulated fertilizers in agriculture.

II. Core components

(I) Raw material pretreatment system

Raw material storage and transportation:

Equipped with a large raw material warehouse, different storage areas are divided according to the type and characteristics of raw materials. Moisture-proof, insect-proof, and ventilation facilities are all available to ensure the stability of raw material quality. Raw material transportation adopts the coordinated operation of belt conveyors and bucket elevators. The belt conveyor runs smoothly and has a large load capacity, and is responsible for horizontal transportation; the bucket elevator is efficient and vertically lifted. The two are seamlessly connected to ensure that raw materials are continuously supplied to the front end of the production line.

Crushing equipment:

The key crushers are mostly hammer or chain crushers. The high-speed rotating hammer or chain exerts strong impact and shear on the block and granular raw materials, crushing them to the ideal particle size, generally controlled at 0.5-3 mm, which is conducive to the subsequent uniform mixing and granulation process. Some advanced crushers also have built-in intelligent screening devices to automatically separate qualified and unqualified materials. Those that do not meet the standards are immediately returned to the furnace for re-crushing.

(II) Batching system

Batching silos and metering devices:

Set up multiple independent batching silos to hold the main raw materials such as nitrogen, phosphorus, potassium and various additives and trace elements. The bottom of the silo is equipped with high-precision electronic scales, spiral feeders and other metering components. The accuracy of the electronic scale can reach ±0.5%, which can accurately monitor the amount of raw materials put in; the spiral feeder feeds materials stably and evenly according to the control system instructions.

Automatic batching control system:

The intelligent control system based on PLC (programmable logic controller) is the soul, pre-storing a large number of fertilizer formulas, covering different crop growth cycles and soil fertility improvement programs. The operator selects the formula with one click, and the system quickly drives each batching bin to accurately discharge the material, adjusts the material ratio in real time, and the error is minimal.

(III) Gear-spinning drum granulation system

Gear-spinning drum granulator body:

The granulator body is made of high-strength alloy steel plates rolled and welded, which is durable and corrosion-resistant. The internal agitators are carefully arranged in a spiral or staggered manner, and the agitators are made of wear-resistant alloy steel with a long service life. When the drum rotates at a uniform speed, the agitators stir and knead the materials in all directions, causing the materials to agglomerate into granules during tumbling. The granulation process is gentle and efficient, which can effectively avoid excessive extrusion of materials and destruction of nutrient structure.

Auxiliary control device:

Equipped with a variable frequency speed regulating motor, it can accurately control the drum speed and flexibly adjust it according to the characteristics of the raw materials and the expected particle size of the particles; at the same time, an intelligent spray device is set to accurately spray binder and water into the drum as needed to optimize the viscosity of the material, ensure the quality of particle forming, and produce particles with uniform particle size, mostly between 2-6 mm, with a forming rate of over 85%.

(IV) Post-processing system

Drying equipment:

Rotary dryers are often used. The specially designed lifting plate inside rotates with the cylinder, constantly lifting the material, allowing it to fully exchange heat with the hot air, quickly evaporate the water, and reduce the moisture content of the particles from 15% – 20% after granulation to the safe storage range (10% – 12%). Some dryers also introduce waste heat recovery technology to save energy and increase efficiency.

Cooling equipment:

Air-cooled coolers are the mainstream choice. High-power fans blow in cold air, penetrate the gaps between particles, take away heat, and restore the particles to normal temperature in a short time, preventing high-temperature particles from agglomerating and deteriorating, which is conducive to subsequent packaging and storage.

Screening and return device:

Use a multi-layer vibrating screening machine to accurately screen according to particle size, and output qualified particles in an orderly manner to the packaging link; unqualified particles (too large, too small) are automatically returned to the granulator for reprocessing through the return belt to ensure that the qualified rate of finished products is always maintained at more than 95%.

III. Production process

The raw materials are sent from the storage warehouse to the crushing equipment through the conveying equipment, and are stored in the batching bin after pretreatment.

The batching system accurately batches the materials according to the established formula, and the evenly mixed materials enter the stirring drum granulator.

The materials are rolled, mixed, and agglomerated into granules in the granulator, and the freshly baked granules enter the drying, cooling, and screening processes in turn.

The finished granules that pass the screening are transported to the packaging area and packaged by the automated packaging equipment; the unqualified granules return to the granulation link along the return path.

IV. Product advantages

Excellent granule quality: The fertilizer granules produced are round, compact, uniform in size, smooth in surface, and good fluidity for mechanized fertilization; the granules have moderate strength, are resistant to transportation and storage extrusion, and have good water solubility, which can quickly provide nutrients for the crop roots.

Balanced and accurate nutrition: Accurate batching and full mixing ensure that the nutrients of each granule are evenly distributed, which meets the nutritional requirements of crops at various growth stages, and the fertilization effect is significant, helping crops to thrive, increase production and improve quality.

High production efficiency: Automation runs through the whole process, each device is closely connected and operates stably, the agitator drum granulator is efficient in granulation, and the production efficiency of the whole line far exceeds that of traditional production lines, which can meet the needs of large-scale and continuous production.

Environmental protection and energy saving are outstanding: the closed production structure is equipped with efficient dust removal and exhaust gas purification facilities, and the dust and harmful gas emissions in the workshop meet the standards; energy-saving measures such as equipment optimization design and waste heat recycling reduce energy consumption, which is in line with the concept of green production and conducive to the sustainable development of enterprises.