Release time:December 6, 2024

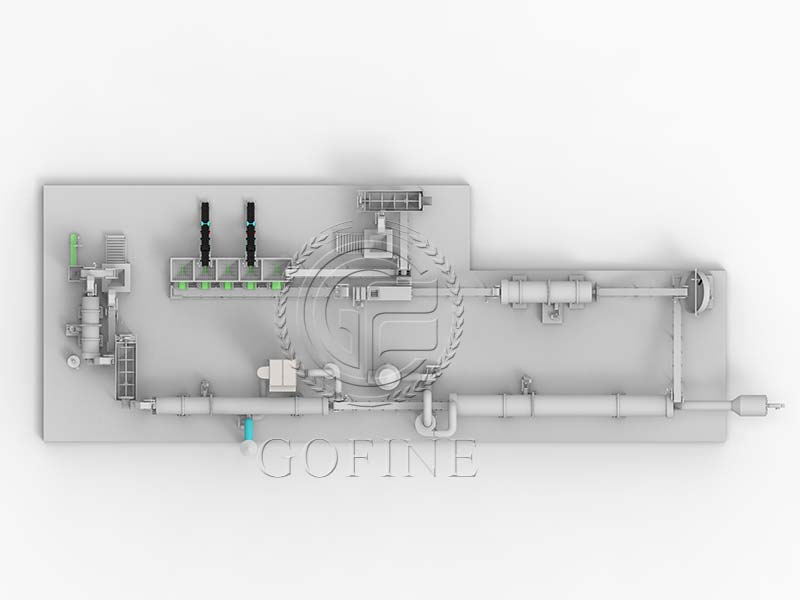

I. Overall overview of the production line

Compound fertilizer drum granulation production line is a comprehensive production line specialized in the production of compound fertilizers. It can transform various basic fertilizer raw materials such as nitrogen, phosphorus, potassium, etc. into high-quality compound fertilizer products with uniform particles and complete nutrients through a series of processing procedures, meeting the dual requirements of modern agriculture for fertilizer quality and production efficiency.

II. Main components

(I) Raw material pretreatment system

Raw material storage facilities

Contains multiple large raw material storage bins for storing basic fertilizer raw materials such as nitrogen fertilizer (such as urea), phosphorus fertilizer (such as monoammonium phosphate, superphosphate), potassium fertilizer (such as potassium chloride, potassium sulfate), and other trace element raw materials that may be added. These storage bins have good sealing properties, which can prevent the raw materials from getting damp and agglomerating, ensuring the stability of the raw material quality.

Raw material conveying equipment

Mainly includes belt conveyors and bucket elevators. Belt conveyors can smoothly convey raw materials in the horizontal direction, and their conveying speed can be adjusted according to production needs. Bucket elevators are used to lift raw materials from low places to high places in production links, such as conveying raw materials to batching bins or crushing equipment to ensure continuous supply of raw materials.

Raw material crushing equipment

When the raw material particles are large or agglomerated, crushing equipment is needed for processing. For example, a hammer mill uses high-speed rotating hammers to impact and shear the raw materials and crush them into fine powder. This allows the raw materials to be more evenly combined in the subsequent mixing and granulation process.

(II) Batching system

Batching bin

There are multiple batching bins, each for a raw material. Precise metering devices such as electronic scales or spiral feeders are installed at the bottom of the batching bin. These metering devices can accurately control the amount of each raw material according to the pre-set compound fertilizer formula to ensure that the proportion of various nutrients in the fertilizer is accurate.

Automatic batching controller

This is the core component of the batching system. It controls the discharge speed and discharge amount of each batching bin through a computer program. The operator can input different compound fertilizer formulas on the controller, and the controller will automatically batch the ingredients according to the formula requirements to achieve an automated and precise batching process.

(III) Mixing equipment

Horizontal mixer

The mixer has a unique stirring device inside, such as a spiral ribbon stirring paddle. When the prepared raw materials enter the mixer, the stirring paddle rotates under the drive of the motor, so that the raw materials can move three-dimensionally in the machine body to ensure that the various raw materials can be fully mixed and evenly mixed. The mixing time and stirring speed can be adjusted according to the properties of the raw materials and the formula requirements. The general mixing time ranges from a few minutes to more than ten minutes.

(IV) Drum granulation system

Drum granulator

This is the key equipment of the production line. Its working principle is that the raw materials are constantly tumbling under the rotation of the drum, and the binder solution is sprayed into the drum through the nozzle. As the drum continues to rotate, the raw materials gradually agglomerate into particles. The parameters of the drum granulator, such as the rotation speed, inclination angle, and the amount of binder sprayed, can be adjusted according to the characteristics of the raw materials and the size and strength of the required particles.

(V) Post-processing system

Drying equipment

The newly granulated compound fertilizer granules contain a certain amount of moisture and need to be dried by drying equipment. Commonly used drying equipment includes rotary dryers, which use a hot air circulation system to send hot air into the dryer, fully contact the granules, and evaporate the moisture. During the drying process, the drying temperature and time must be controlled to avoid overheating of the granules and nutrient loss.

Cooling equipment

The temperature of the granules after drying is high and needs to be cooled by cooling equipment. Usually, an air-cooled cooler is used to blow cold air into the cooler through a fan to quickly reduce the temperature of the granules and restore them to normal temperature. This can prevent the granules from agglomerating during storage.

Screening equipment

Used to screen out granules that do not meet the specifications, such as granules that are too large, too small, or irregularly shaped. Qualified granules are transported to the finished product packaging area, and unqualified granules are returned for reprocessing. Screening equipment generally uses a vibrating screen, and the mesh size can be changed according to the size requirements of the granules.

III. Production process

Raw materials are transported from the storage bin to the pretreatment system through conveying equipment for pretreatment such as crushing.

The pretreated raw materials enter the batching system and are accurately batched according to the set formula.

The prepared raw materials are fully mixed in the mixing equipment.

The mixed raw materials enter the drum granulator and are granulated under the action of the binder.

The granulated particles are dried, cooled and screened in turn. The qualified finished products are packaged and the unqualified particles are returned for reprocessing.

IV. Product advantages

Good particle quality

The compound fertilizer particles produced by drum granulation are uniform in size, regular in shape, moderate in hardness, with good fluidity and dispersibility, which is convenient for mechanized fertilization. At the same time, the nutrients of the particles are evenly distributed, which can provide a balanced nutrient supply for crops.

Flexible formula

The batching system can accurately control the proportion of various raw materials, produce compound fertilizer formulas that meet the needs of different crops and different soils, and provide a variety of fertilizer options for agricultural production.

High production efficiency

The entire production line has a high degree of automation, and each link is closely coordinated, which can achieve continuous and stable production, greatly improving the production efficiency of compound fertilizer and suitable for large-scale production.

Environmental protection and energy saving

The production line adopts a series of environmental protection measures, such as dust collection devices and exhaust gas treatment systems, to reduce environmental pollution during the production process. At the same time, optimized production processes and equipment selection also help reduce energy consumption.